Ballard launches FCmove-SC fuel cell at Busworld: improved performance and lifecycle cost on the road to diesel parity

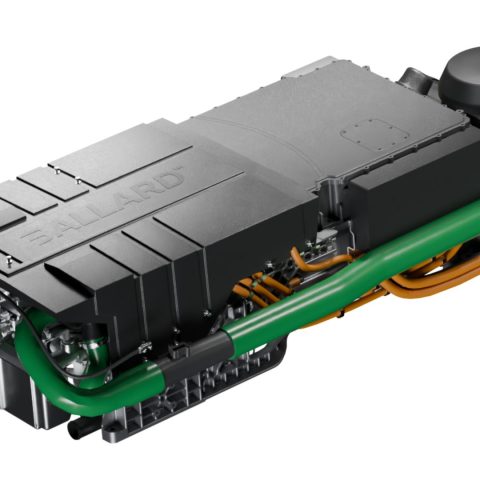

Ballard Power Systems launches its new-generation transit fuel cell module, the FCmove®-SC, at Busworld in Brussels. Designed for city transit duty, the FCmove®-SC builds on Ballard’s market-leading FCmove® family to deliver greater sustained power, simplified vehicle integration, improved in-service performance, and lower lifecycle cost as part of Ballard’s roadmap toward diesel parity.

This content is authored by Ballard Power Systems and belongs to the series Busworld Spotlight, offering a dedicated space to companies presenting their vision, products, strategies and innovative solutions in the run-up to Busworld Europe 2025, from October 4–9 in Brussels, Belgium – and beyond.

Ballard Power Systems is exhibiting in Hall 9, Stand 957.

Fuel cell electric buses are moving beyond pilots into growing commercial fleets. They deliver operational strengths – rapid refuelling, long range, and consistent performance across hot and cold weather – but historically carry a total cost of ownership (TCO) premium compared to diesel, and in many cases versus battery electric buses.

That premium depends mainly on hydrogen price, vehicle acquisition cost, and duty cycle profile. Less obvious, but decisive, is how fuel cell module design and powertrain architecture impact those inputs.

Ballard Power Systems launches its new-generation transit fuel cell module, the FCmove®-SC, at Busworld in Brussels. Designed for city transit duty, the FCmove®-SC builds on Ballard’s market-leading FCmove® family to deliver greater sustained power, simplified vehicle integration, improved in-service performance, and lower lifecycle cost as part of Ballard’s roadmap toward diesel parity.

“The FCmove®-SC is the latest product on Ballard’s core product platform, which anchors broader advances targeting the industry’s core challenge: narrowing the gap in cost of ownership parity with legacy diesel systems,” says Kevin Colbow, Senior Vice President and Chief Technology Officer, Ballard. “The fuel cell design significantly reduces integration complexity for bus manufacturers while improving life-time cost and performance for transit operators.”

Key enhancements for bus manufacturers and operators include:

- 25% increase in volumetric power density through integrated DC/DC packaging

- 25% higher maximum radiator outlet temperature (60°C → 75°C), simplifying vehicle thermal management

- 40% reduction in total part count

Lower lifecycle cost, better performance

The FCmove®-SC targets a peak power capability of at least 75kW, optimized for consistent in-service output and higher thermal margins for improved efficiency. These attributes support smaller cooling requirements and provide more usable waste heat for cabin heating – all designed to reduce operating cost and enable competitive total cost of ownership versus legacy diesel systems. Efficient subsystems support an expected service life of approximately 25,000 operating hours under standard transit duty cycles.

Simpler integration

By internalizing the DC/DC converter and power controller, the FCmove®-SC consolidates functionality into a smaller, more serviceable package. Fewer external interfaces and routable parts simplify powertrain integration and reduce diagnostics and preventive maintenance requirements.

Intelligent services

Ballard upgrades its fleet services to pair the FCmove®-SC with predictive maintenance and analytics. Onboard communications and Ballard’s FCServiceCloud Customer Insight portal enable preventive and predictive maintenance workflows, helping operators maximize uptime and lower lifecycle support costs.

Enhanced safety

Enhanced safety is central to the FCmove®-SC architecture, which introduces industry-leading safety features. The PEM stack enclosure incorporates a new internal geometry that inhibits hydrogen-related risks. This passive safety measure reduces dependence on conventional active safety features such as sensors and software controls.

Proven field performance

The FCmove®-SC draws on Ballard’s extensive on-road experience. In Europe, Ballard has deployed more than 850 vehicles across cities on the continent. Ballard’s FCmove®-HD module has been produced, scaled, and successfully operated over nearly a hundred million service kilometers. This operational base informs FCmove®-SC’s new design, architecture, and component subsystems, resulting in lower total cost of ownership for transit operators.

“Our focus is to deliver practical, measurable steps that move fuel cell buses closer to diesel parity,” adds Colbow. “We benefit from the most operational experience in the bus segment and insights from our long-standing customers to deliver a solution that simplifies vehicle integration, reduces operating and maintenance costs, and provides services that keep fleets reliably on the road.”

Ballard exhibits the FCmove®-SC and other transit solutions in Hall 9, Stand 579 at Busworld Brussels. Demonstrations are by invitation; transit operators and OEMs interested in scheduling should contact Ballard’s marketing team.