The Ultra Press 2 project to optimize fuel cell manufacturing

The long march towards the completion of the energy transition. One of the indispensable steps in this process goes through the production of bipolar plates, or rather, the mass production of fuel cells. In this regard, the Ultra Press 2 project is making rapid progress. In the Ultra Presss project, the basis for an innovative […]

The long march towards the completion of the energy transition. One of the indispensable steps in this process goes through the production of bipolar plates, or rather, the mass production of fuel cells. In this regard, the Ultra Press 2 project is making rapid progress.

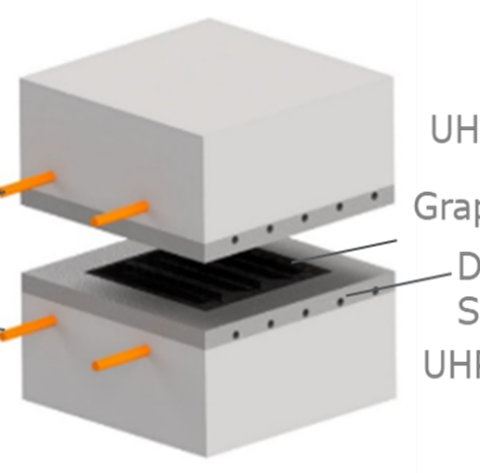

In the Ultra Presss project, the basis for an innovative hot pressing process with a tool made of ultra-high strength concrete, called “Ultra-High Performance Concrete” (UHPC), has been created and its suitability proven.

The research object is used for the production of graphite-based bipolar plates for NT-PEM (low-temperature polymer electrolyte) fuel cells. By means of the implication of inductive temperature control, the usual bottlenecks of hot stamping can be eliminated, e.g. long cycle times and high energy consumption due to the necessary heating and cooling steps. The process now started with a pressing tool made of special cement can hot press the graphite-based bipolar plates in seconds.

As far as cost and time savings are concerned, the production process is to be further developed and converted to series production in the follow-up project UltraPress2. Since its official launch in October 2021, it has received four years of funding from the program of the German Federal Ministry of Economics and Energy.

The Ultra Press 2 project

The direct partners belonging to the project consortium are “Proton Motor Fuel Cell GmbH”, “Boyke Press Technology GmbH”, “Eisenhuth GmbH & Co. KG”, “Runkel Fertigteilbau GmbH” and the “Institute for Design and Production in Precision Engineering at the University of Stuttgart” (IKFF) plus the “Center for Fuel Cell Technology” (ZBT) and associated companies such as “MC-Bauchemie Müller GmbH & Co. KG” and “eldec Induction GmbH”.

In the current “Ultra Press 2” approach, inductive heating of the composite material – including the use of ultra-high strength concrete as a pressing tool – must be tracked. This combination allows fast heating and cooling cycles, whereby only a very small part of the steel mass is specifically heated compared to a conventional steel tool. In addition, a significant improvement in product quality can be achieved, to which the more homogeneous heating of the compound material caused by induction and the targeted control of solidification contribute.

New hot pressing process to be implemented in demonstration plant for production of bipolar plates

The focus of the research is on the component dimensions of the two Proton Motor “PM 200” and “PM 400” hydrogen fuel cells. With a series of tests at the cleantech specialist in Puchheim, the proprietary design of the bipolar plate is to be examined for final qualification. In addition, ZBT’s expertise and machinery in the field of hydraulic presses and hot stamping must be expanded during the transport period. For this purpose, a fully automatic laboratory press, which enables hot stamping of bipolar plates, as well as monitoring and optimization. In addition to the further reduction of process times and the downsizing of pressing tools, the project objective includes the implementation of the new inductive hot pressing process in a demonstration plant for the automated, pre-series production of bipolar plates.