From drives to batteries: ABB Traction’s offer (and strategy) for the electric bus market

At Busworld Europe 2025, ABB Traction presented its latest solutions for heavy-duty electric buses. In the spotlight there were the HES580 three-level inverter and the AMXE250S central motor, as well as high-performance LTO batteries. In this interview, Andreas Z’Graggen, Global Head of Energy Storage Systems at ABB Traction (ABB’s division responsible for powertrain components), discusses […]

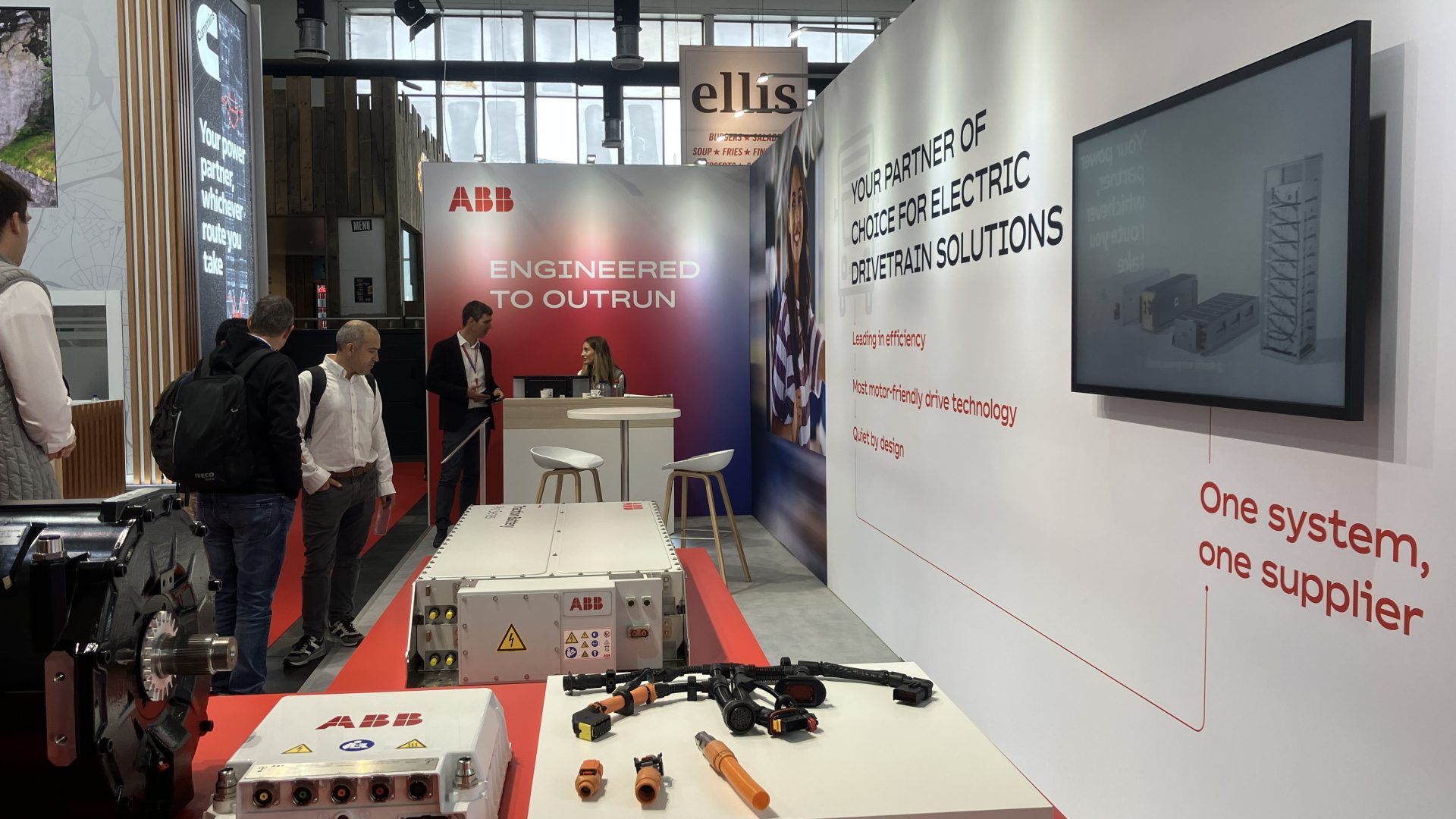

At Busworld Europe 2025, ABB Traction presented its latest solutions for heavy-duty electric buses. In the spotlight there were the HES580 three-level inverter and the AMXE250S central motor, as well as high-performance LTO batteries.

In this interview, Andreas Z’Graggen, Global Head of Energy Storage Systems at ABB Traction (ABB’s division responsible for powertrain components), discusses ABB’s latest innovations for heavy-duty electric buses, and the approach of the company to bus electrification.

Speaking of batteries, there is definitely a sweet spot in the bus sector for LTO batteries. However, we remain open to new battery technologies.

Andreas Z’Graggen, Global Head of Energy Storage Systems, ABB Traction

We are also exploring NTO, a niobium-based chemistry similar to LTO but with higher energy density, allowing more energy in the same volume while maintaining safety, robustness and to some extent longevity.

At the end, we’re cell-agnostic, screening all technologies—from LFP to NTO to upcoming solid-state solutions. We rigorously test performance and match batteries to mission profiles before deployment. ABB’s value lies in packaging know-how, laser welding, BMS, control algorithms, functional safety, and system integration, regardless of cell chemistry.

Andreas Z’Graggen and the plus of the combo motor – inverter

When it comes to the bus business, you showcased at Busworld a series of new products. Could you briefly describe them?

I’d start with our new HES580 Mobile Inverter, a three-level converter built on IGBT technology and perfectly matched to our motor. The HES580 can also be paired with non-ABB motors very efficiently. This design significantly improves efficiency, delivering up to 8% fuel savings. In addition, it reduces stress on the motor, compared to SIC-Technology where you have increased stress on the motor winding, lowers heat generation, and minimizes maintenance requirements, making it an ideal solution for heavy-duty electric buses.

What about the motor, then?

The AMXE250S is ABB’s compact permanent magnet synchronous motor designed specifically for heavy-duty electric buses. When paired with ABB’s HES580 three-level inverter, preliminary testing on the UITP SORT 1 duty cycle shows energy savings of around 8% compared with conventional two-level inverters. Our permanent magnet central motor is compact, high torque at low speed, and designed for buses. It’s optimized with our three-level drive. There’s value in the package, but OEMs can mix-and-match with other components. For buses, we focus on the central motor layout, not wheel hub motors axles.

Do you provide the motor and drive as an integrated package? Or do you sell motors and drives separately?

Both. ABB Traction offers a complete motor-drive solution, which can also be purchased independently, though the package offers optimized efficiency and reduced stress. Its distinguishing feature is the three-level topology. Unlike conventional two-level drives, the three-level setup acts like a dimmer, producing a smoother waveform to the motor. This reduces stress, improves efficiency, and extends motor life. While ABB optimizes the motor and drive together, they can also be used independently. The same applies to our batteries: the package adds value, but purchasing separately is perfectly feasible, and many customers do so.

ABB’s battery focus is now on LTO. But in the future…

Indeed, you also have a battery pack at the stand…

Yes, for buses we also supply high-performance LTO batteries. We originally started in railway applications, where duty cycles are extremely demanding. This makes LTO batteries ideal not only for rail but also for certain bus applications. We have a strong track record with trolleybuses, which charge under overhead lines and can flexibly extend their routes and don’t need a diesel backup. Additionally, these batteries support ultra-fast charging, with concepts such as “flash charging” for 30 seconds at alternating stops, and they are also suitable for fuel cell buses.

Of course, LTO doesn’t cover all market needs—especially for buses that rely on overnight charging, which require chemistries more similar to those used in cars.

It’s very expensive compared to LFP, right? Are you also working on other chemistries?

LTO might appear expensive compared to other technologies like LFP during the initial investment. But what really needs to be compared is the cost per kWh throughput. There is definitely a sweet spot in the bus sector for LTO batteries, such as trolley or hybrid applications. It always depends on the duty cycle around which the business case is built.

We remain open to new battery technologies. We have an established screening process, where our scientists work with Tier 1 cell suppliers, test samples in-house, and match performance to specific applications. While LFP is now cheaper and its lifetime is improving, we carefully evaluate data against real-world performance before introducing it to the market.

Beyond LFP, we are also exploring NTO, a niobium-based chemistry similar to LTO but with higher energy density, allowing more energy in the same volume while maintaining safety, robustness and to some extent longevity. At the end, we’re cell-agnostic, screening all technologies—from LFP to NTO to upcoming solid-state solutions.

We rigorously test performance and match batteries to mission profiles before deployment. ABB’s value lies in packaging know-how, laser welding, BMS, control algorithms, functional safety, and system integration, regardless of cell chemistry.

What is ABB’s contribution to battery production?

We purchase the cells and handle everything from there. ABB manages mechanical packaging, cooling, electronics, control algorithms, and battery management systems—essentially creating the full modules and packs.

ABB Traction offers a complete motor-drive solution, which can also be purchased independently, though the package offers optimized efficiency and reduced stress. Its distinguishing feature is the three-level topology. Unlike conventional two-level drives, the three-level setup acts like a dimmer, producing a smoother waveform to the motor. This reduces stress, improves efficiency, and extends motor life.

Andreas Z’Graggen, Global Head of Energy Storage Systems, ABB Traction

The production chain of ABB batteries

Your production is global: could you explain where the work is done?

The core assembly and laser welding—a critical quality step—takes place in Switzerland with full automation. Some final assembly is done in Germany, labor-intensive work in Poland, and we can also localize production near key markets, such as the U.S., to meet requirements like Buy America. This approach leverages our global footprint while maintaining high-quality standards.

May you be specific about the sourcing of cells? Do you see any chance for a European supply chain in this regard?

Currently mostly Asian suppliers, but we monitor global options, such as European cell manufacturers. These initiatives take time and are challenging to master. Significant investment is required to establish a complete local supply chain. We follow very interesting projects, but ultimately, our focus remains on verifying cell quality, ensuring they meet the required mission profiles, and then integrating them into our battery systems.

Still on batteries, how large is your annual production, and what is your market share in buses?

The majority of our production is still for railway applications, producing thousands of battery modules with an annual capacity of roughly 100–200 MWh, scalable via multiple shifts. The bus segment is smaller but drives exploration of new chemistries, since LTO remains a niche solution.

Are you pursuing a cell-to-pack approach?

Yes, our latest portfolio extension – the Pro Series traction batteries – features a cell-to-pack approach, which allows us to push the limits of energy density on pack level. For railways, modular designs work well when using multiple units per train. At the same time, we also have a strong engineered-to-order mindset, allowing custom geometries while keeping the inner packs modular — like playing with LEGO blocks.

Back to motors, are you also looking at the future potential integration of in-wheel motors in your offer?

We currently have no plans to pursue axle-mounted solutions. We favor central-mounted motors because of their reliability and impact on unspring mass. They are also easier to cool and improve efficiency and durability compared to in-wheel designs.

Are you supplying the motor to HESS or other customers?

We are supplying motors to Hess for the e-bus market – we began our relationship with them 10 years ago in Switzerland and we have a strong partnership. We are also supplying motors to other industries as well, including mining and construction.