BYD launches the B13.b Low Entry intercity bus at UITP Summit

BYD has launched in Hamburg, on the occasion of UITP Summit 2025, the intercity Low Entry model B13.b. Based on BYD’s self-developed Blade Battery technology (which is manufactured with BorgWarner) and 13.2-meters long, the BYD eBus B13.b offers a maximum battery capacity of 560 kWh. With a top speed of 100km/h and a range of […]

BYD has launched in Hamburg, on the occasion of UITP Summit 2025, the intercity Low Entry model B13.b. Based on BYD’s self-developed Blade Battery technology (which is manufactured with BorgWarner) and 13.2-meters long, the BYD eBus B13.b offers a maximum battery capacity of 560 kWh.

With a top speed of 100km/h and a range of up to 700 km, the new BYD eBus B13.b “is engineered to offer operators optimum flexibility, with the ability to master both urban and intercity duties”, BYD states. The B13.b can accommodate up to 78 passengers, including up to 49 seats – a significant increase in the carrying capacity of the previous B13 model, which remains on sale at present and can accommodate up to 70 passengers, as BYD underlines.

BYD launches B13.b Low Entry at UITP Summit

BYD Blade Battery technology, based on LFP formula, sits at the heart of the new BYD eBus B13.b. It provides, according to the manufacturer, a volume utilization efficiency 50% greater than traditional battery packs, leading to enhanced energy density and therefore longer driving range.

With the BYD eBus B13.b, battery capacity has increased by 54 kWh. While the overall bus weight remains similar to the previous model, the estimated maximum range has increased to 700km (provisional data, Standardized On-Road Test (SORT) cycle) for the 560kWh version and 620km for the 476kWh version.

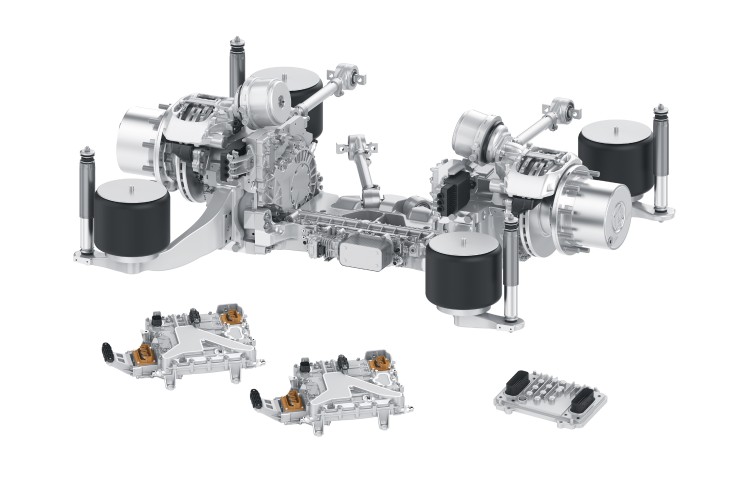

The BYD B13.b is equipped with two 150kW wheel hub hairpin motors. BYD’s proprietary integrated Thermal Management System seamlessly integrates drivetrain cooling, battery cooling, battery heat pump heating, and drivetrain waste heat recovery. This has enabled BYD to increase the heating speed of the B13.b Blade Battery, while reducing energy consumption by 10% on the test cycle, still quoting from BYD’s press note.

The BYD eBus B13.b takes full advantage of BYD’s proprietary Blade Chassis Battery, which made its global production debut on the BYD eBus B12 in 2024. The Cell-to-Chassis technology integrates the BYD Blade Battery packs within the chassis, enabling them to form part of the structure and providing numerous advantages, that the manufacturer explains so: “The sandwich structure used reduces weight and significantly enhances energy efficiency. The vehicle’s torsional stiffness is a highly impressive 56,983Nm/°, delivering improved ride comfort, handling and refinement. Compared with the previous model, the center of gravity of the B13.b has been reduced by 30%, while the vehicle’s maximum tilt angle has increased by 31%, further enhancing safety, stability and maneuverability”.

BYD 6-in-1 controller on B13.b bus model

The new B13.b is equipped with BYD’s proprietary 6-in-1 controller, incorporating Silicon Carbide (SiC) technology, which reduces weight by 14% and decreases volume by 40% compared to traditional controllers, and improves operating efficiency to 98.5%. It integrates six key electric components in one compact module, comprising the two electric motor control units, the steering control unit, the air compressor controller, the DC-DC converter, and the power distribution unit.

What about charging options? The bus can be charged with a single 192kW gun, or dual 192kW guns, and a maximum charging power of 500 kW with the use of a pantograph.