Inside Cummins’ multi-energy strategy for the bus market: from LFP batteries to Euro VII, gas and hydrogen engines

At Busworld Europe 2025, Cummins showcased a technology portfolio that spans batteries, combustion engines, hydrogen and natural gas—reflecting the different speeds and needs of the global bus market. The company’s strategy combines zero-emission development with continued investment in advanced combustion platforms, acknowledging that operators across regions are moving toward decarbonisation through multiple pathways. To explore […]

At Busworld Europe 2025, Cummins showcased a technology portfolio that spans batteries, combustion engines, hydrogen and natural gas—reflecting the different speeds and needs of the global bus market. The company’s strategy combines zero-emission development with continued investment in advanced combustion platforms, acknowledging that operators across regions are moving toward decarbonisation through multiple pathways.

To explore these parallel tracks, we spoke with Mahendra Kumbhar, Battery Systems Customer Engineering Manager at Accelera by Cummins, the zero emission brand launched in 2023, and Cenk Yavuz, Director of Europe Bus Business at Cummins. Their perspectives highlight how the company is advancing both next-generation electric solutions and the engine technologies that continue to support many applications and geographies.

Source pictures: Busworld

Accelera By Cummins: LFP is the way for the e-bus market

Mahendra Kumbhar, can you describe the battery technology Cummins has been presenting at Busworld?

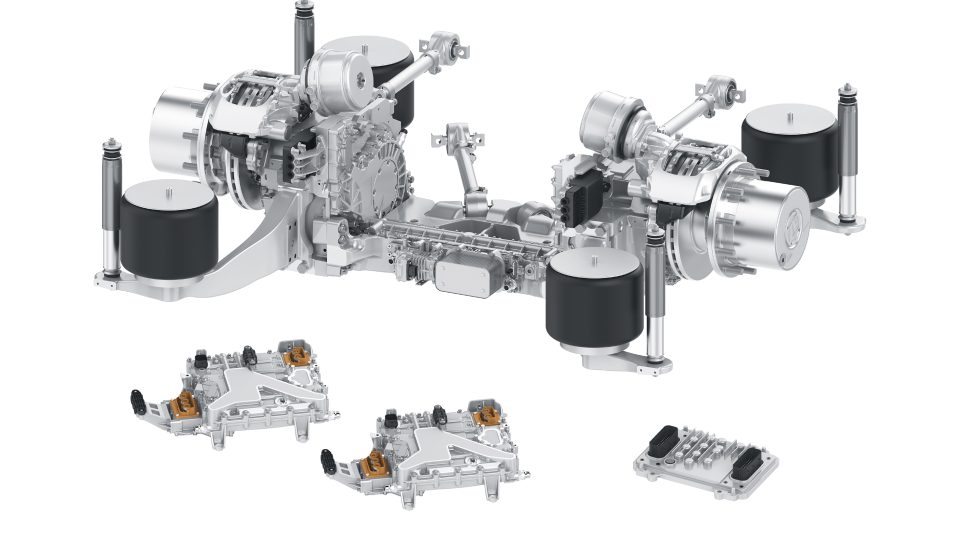

M.K.: We have been introducing our newest generation of lithium iron phosphate (LFP) battery packs. These packs are modular and use advanced LFP technology to provide higher volumetric and gravimetric energy density.

How does the energy density compare to older LFP or NMC batteries?

M.K.: Older LFP batteries have around 145 Wh/kg. Our new packs achieve about 165 Wh/kg, approaching the levels of NMC batteries while retaining the advantages of LFP in terms of safety, cycle life, and total cost of ownership. They also support higher C-rates compared to NMC.

Production will be in Europe for the one-tier battery packs headed to the transit bus market. They will be introduced in 2028. Our 3T variant will be in production in 2027 in North America. We have additional variants that we will localize based on customer demand.

Mahendra Kumbhar, Battery Systems Customer Engineering Manager, Accelera by Cummins

We see a clear shift underway in Europe from NMC to LFP for buses…

M.K.: Yes. For city buses and coaches in Europe, advanced LFP is becoming the preferred chemistry. This is due to lower cost, higher safety—especially in thermal propagation—and longer cycle life, which means fewer battery replacements over the lifetime of the bus.

What warranty do you offer on these batteries?

M.K.: Warranty depends on duty cycles and application conditions, such as city buses versus coaches and the charging profile.

Do you also offer NMC batteries?

M.K.: We do, primarily in North America for transit and school buses. For Europe, we are primarily focused on LFP because of the cost efficiency and longevity benefits, the key value drivers we see in the European market.

The roadmap of Cummins-made batteries

How is the pack integrated into the vehicle?

M.K.: The packs use a cell-to-pack architecture, eliminating modules. In the “cell-to-chassis” design, the pack can be mounted directly under the floor, becoming a structural, load-bearing part of the bus chassis. For example, our one-tier pack at 140 mm height fits under the floor and allows passenger seats to be mounted directly on it.

Who are your main European customers for these packs?

M.K.: We are unable to disclose specific customer names at this time.

When will these packs enter production, and where?

M.K.: Production will be in Europe. The one-tier pack, headed to the transit bus market, will be introduced in 2028. Our 3T variant will be in production in 2027 in North America. We have additional variants that we will localize based on customer demand.

Older LFP batteries have around 145 Wh/kg. Our new packs achieve about 165 Wh/kg, approaching the levels of NMC batteries while retaining the advantages of LFP in terms of safety, cycle life, and total cost of ownership. They also support higher C-rates compared to NMC

Mahendra Kumbhar, Battery Systems Customer Engineering Manager, Accelera by Cummins

How does Cummins’ approach compare to competitors like CATL or BYD?

M.K.: Some competitors utilize cells optimized for the passenger vehicle market because that is where most of the EV volume sits today. However, the cell Accelera by Cummins leverages is specifically designed and optimized for commercial buses and trucks. This allows us to optimize geometry, chemistry, and duty cycle performance. Building packs in North America and leveraging cells from our joint venture, Amplify Cell Technologies, also provides advantages like qualifications for USMCA and Buy America.

But Cummins’ zero-emission work is only one part of a broader puzzle. While Accelera pushes forward with bus-specific LFP battery architectures, the combustion and gas portfolio remains essential in markets where duty cycles, cost constraints or infrastructure realities make electrification more gradual. This explains why Cummins continues to develop Euro VI and Euro VII engines, expand its natural-gas offering and invest in hydrogen combustion as a longer-term option.

With this wider context in mind, the second interview turned to Cenk Yavuz, Cummins’ Director of Europe Bus Business, who outlines how diesel, gas and hydrogen technologies fit into Europe’s evolving regulatory landscape and why a multi-energy strategy remains central to Cummins’ approach.

Diesel still represents the majority of our sales in the bus segment. Natural gas accounts for about 20 to 25 percent, while diesel makes up the remaining 75 percent. A few years ago, gas engines were only around 10 to 15 percent, so there’s been a steady increase. We believe demand will remain solid at least until the Euro 7 stage, especially as natural gas can help operators reduce CO2 emissions under the current regulatory framework.

Cenk Yavuz, Director of Europe Bus Business at Cummins

Cenk Yavuz, which are the main innovations Cummins showcased at Busworld 2025?

C. Y.: One of our key highlights is the new Euro VI version of our X10 HELM engine. The X10 was originally launched for Euro 7, but due to customer demand driven by changes in the Euro 7 implementation timeline, we have now launched a Euro 6 variant. The 10-litre HELM platform is common across our Euro VI and Euro 7 X10 products, though each engine will have specific technologies to meet the relevant legislation.

So the same architecture will be used for Euro 7?

C. Y.: Not exactly the same, though both engines have a common space claim and integration points. Some components will be advanced or modified for Euro 7, but the base platform remains the same for easier integration between the two emissions standards. The X10 Euro VI engine is suitable for both city buses and coaches, delivering up to 454 horsepower and 2,200 Nm of torque. With this, we now cover the full range of bus and coach applications within our portfolio.

How do you see the future of diesel engines in the bus segment? Is there still room for growth?

C. Y.: Cummins operates across a broad range of technologies — diesel, natural gas, hybrid systems, batteries, and full electric traction. We believe there will still be demand for diesel engines, especially at Euro 7 in segments like inter-urban bus and coach where duty-cycles tend to be heavier. Additionally, we anticipate demand from regions that are earlier in their energy transition and will continue to require high-efficiency diesel city buses for some years yet.

Cummins is also developing a hydrogen combustion engine. Can you tell us more about that?

C. Y.: Yes, this is our 6.7-litre B6.7H hydrogen internal combustion engine. It delivers around 290 horsepower and 1,200 Nm of torque. We have already delivered engines from our dedicated production facility in Jamshedpur, India to Tata Motors for field testing, and we plan to have one demonstration vehicle in Europe next year (a few days after the interview was held, Cummins and Anadolu Isuzu disclosed that they are going to work on a Kendo demonstrator)

Hydrogen combustion engines: challenges and opportunities

Where do you see the main barriers or opportunities for hydrogen internal combustion engines in Europe?

C. Y.: There are several factors at play. The hydrogen refuelling infrastructure in Europe is still limited, and the investment cost remains high — this is a challenge for both fuel cell and hydrogen ICE technologies. For now, we expect hydrogen combustion to remain a niche market, but it could serve specific applications. We keep monitoring the market closely because it’s evolving rapidly, and we do see potential emerging in certain regions.

Cummins operates across a broad range of technologies — diesel, natural gas, hybrid systems, batteries, and full electric traction. We believe there will still be demand for diesel engines, especially at Euro 7 in segments like inter-urban bus and coach where duty-cycles tend to be heavier.

Cenk Yavuz, Director of Europe Bus Business at Cummins

You’re also exhibiting your L9N natural gas engine. What is driving renewed interest in gas technologies?

C. Y.: The L9N has been in production for more than ten years and is one of our most proven and reliable products. We’re seeing increasing demand again for natural gas engines — they act as a bridge technology toward lower-emission solutions. With renewable natural gas (RNG) becoming increasingly available, the technology makes sense for users who want to decarbonize on a wheel to wheels basis.

How does the market currently split between diesel and gas engines in Europe?

C. Y.: Diesel still represents the majority of our sales in the bus segment. Natural gas accounts for about 20 to 25 percent, while diesel makes up the remaining 75 percent. A few years ago, gas engines were only around 10 to 15 percent, so there’s been a steady increase. We believe demand will remain solid at least until the Euro 7 stage, especially as natural gas can help operators reduce CO2 emissions under the current regulatory framework.