From weight reduction to ride dynamics: inside JOST’s BusLink articulation system

From articulated bus articulation and lightweight design to predictive maintenance and cybersecurity, JOST is addressing the technical and operational challenges of modern buses. We discussed these topics with Roland Ramirez, Director of Program Management Global BusLink at JOST, who shares insights on how the BusLink system is designed, produced, and adapted for global bus markets. Ramirez also highlights innovations in dampers, bellows, and control units, as well as future developments and plans to present JOST’s solutions to operators and manufacturers worldwide.

Sponsored by JOST

From articulated bus articulation and lightweight design to predictive maintenance and cybersecurity, JOST is addressing the technical and operational challenges of modern buses.

We discussed these topics with Roland Ramirez, Director of Program Management Global BusLink at JOST, who shares insights on how the BusLink system is designed, produced, and adapted for global bus markets. Ramirez also highlights innovations in dampers, bellows, and control units, as well as future developments and plans to present JOST’s solutions to operators and manufacturers worldwide.

We produce the articulation for the articulated buses of a international OEM, but our facility is streamlined to support additional business. Our goal is to achieve a European market volume of approximately 2,000–2,500 units per year. All in all, we estimate that every year around 7,000 articulated buses are registered worldwide.

Roland Ramirez, Director of Program Management Global BusLink at JOST

Roland Ramirez: JOST history and the bus market

Could you give us an overview of JOST and how the company entered the bus market?

JOST has a history spanning over 70 years, primarily in the production of systems, modules, and components for commercial vehicles. Our entry into the bus market was motivated by a international OEM, with whom we have a strong relationship in the truck business for 30–40 years. Discussions began around 2012, and in 2017 we received the nomination for the BusLink system in Brazil. The core of our bus articulation technology is the turntable bearing, which we’ve been developing since 1952. Our expertise in connecting vehicles, combined with welding know-how, made it natural to extend into articulated buses, using a welded construction rather than casting for weight and flexibility advantages.

How is JOST structured to support bus applications?

Globally, JOST has over 7,500 employees. Our BusLink development team at headquarters comprises around 15 people, focusing on development, purchasing, and testing. Production is located in Poland, where we have a dedicated line for BusLink including automated welding, machining, cathodic dip coating, and full assembly of articulation, bellows, and energy lines. Production runs in two shifts with roughly 20 people per shift.

What is the current production capacity for the bus link system?

We produce the articulation for the articulated buses of a international OEM, but our facility is streamlined to support additional business. Our goal is to achieve a European market volume of approximately 2,000–2,500 units per year. All in all, we estimate that every year around 7,000 articulated buses are registered worldwide.

JOST BusLink is ready for series production

Where does the BusLink system currently stand in terms of production and deployment?

The BusLink system is ready for series production. Production release for the international OEM is scheduled for the end of this year, with pre-series starting shortly after. The design is fully approved, and all durability and winter tests have been completed.

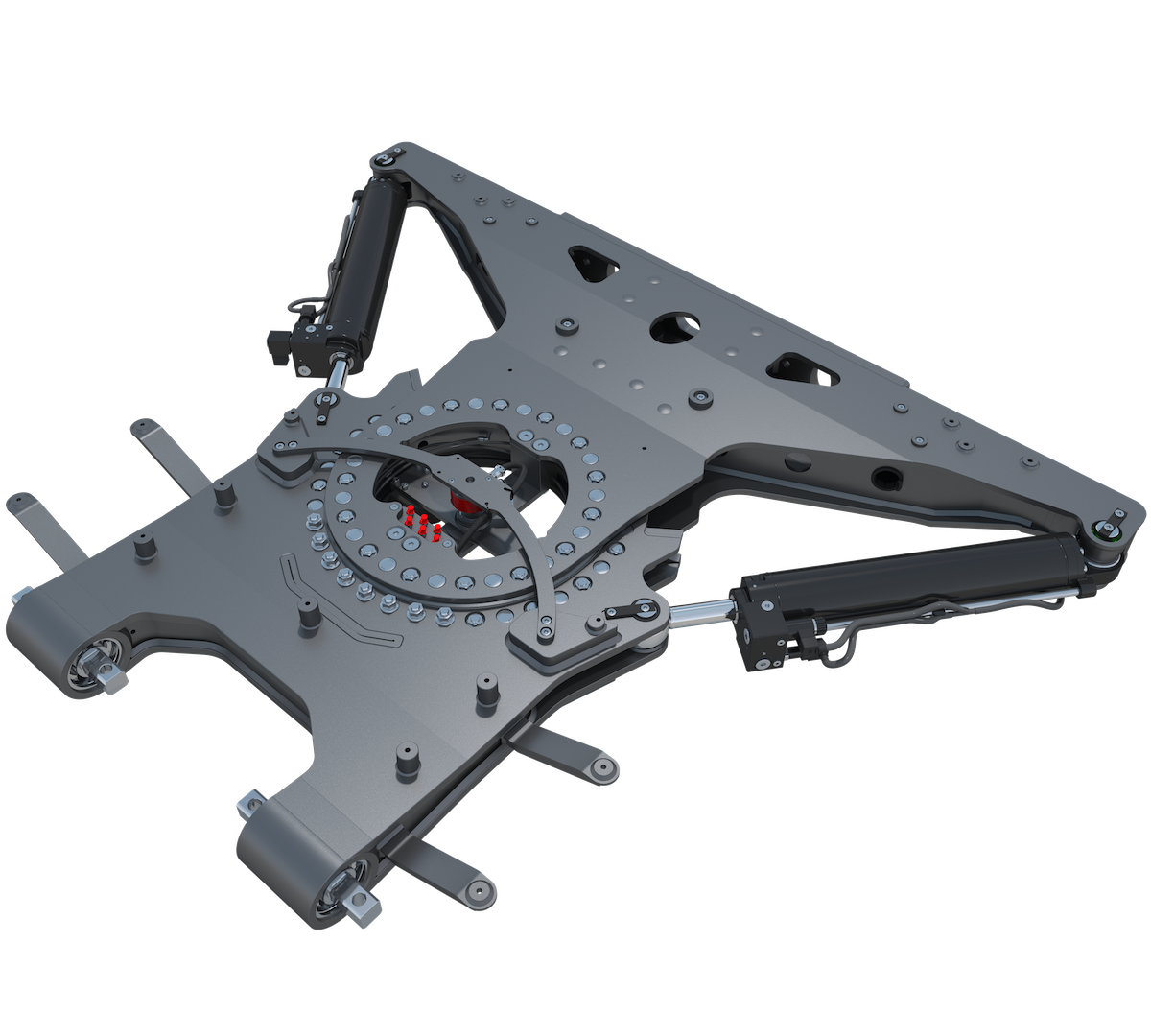

Can you outline the key technological strengths of your bus articulation system?

One of our core focuses is weight reduction. Using welded construction rather than casting provides an initial 8–10 percent weight saving.

Equally important, welded construction allows much greater flexibility in adapting the design to customer-specific needs. Casting tools of this size are extremely expensive, and every customer tends to have slightly different layout or integration requirements. With our approach, customers can modify the articulation geometry or interface points without investing in new tooling. For example, the damper cylinders can be mounted directly onto the chassis using standard fixation points. Since the front and rear connection interfaces are standardized across the market, this modularity enables quick customization without additional industrial investment.

The damper cylinder system is another core differentiator.

Why?

This is the component drivers most directly perceive in terms of handling and ride stability, and this means the velocity of the damper is very important. Our design integrates the damper and hydraulic tank into a single sealed unit, eliminating the need for an external wet kit and minimizing the risk of air suction.

A key engineering challenge is preventing air or foam formation inside the damper, as this would delay pressure recovery and reduce damping force. Our system ensures that the damping pressure — typically around 240 bar — stabilizes again within half a second after passing through the zero point.

We’ve also optimized the damper’s internal volume and pressure characteristics. Compared to typical market designs, our dampers operate closer to their nominal pressure limits (around 90% of capacity versus 80% for many competitors). This design choice reduces the required oil volume, minimizing weight and response time, while maintaining full operational safety margins.

Finally, a visible but often underestimated component is the bellows system. While mechanical performance is hidden inside the articulation, the bellows are the most visible part for both operators and passengers. Over time, many bellows show sagging, with aluminum lamellas becoming misaligned due to material relaxation. We addressed this by developing stiffer raw materials that maintain their structural tension over years of operation. This reduces sagging significantly and preserves a clean, parallel appearance throughout the vehicle’s life — a small but important aspect for quality perception in fleet operation.

Our entry into the bus market was motivated by a international OEM, with whom we have a strong relationship in the truck business for 30–40 years. In 2017 we received the nomination for the BusLink system in Brazil. The core of our bus articulation technology is the turntable bearing, which we’ve been developing since 1952. Our expertise in connecting vehicles, combined with welding know-how, made it natural to extend into articulated buses, using a welded construction rather than casting for weight and flexibility advantages.

Roland Ramirez, Director of Program Management Global BusLink at JOST

Next generation range is already under development

How is JOST addressing evolving market requirements?

We are actively developing the next-generation BusLink articulation system with a strong focus on three priorities: weight reduction, improved isolation, and advanced lighting integration.

Weight remains the top priority. At the same time, we are incorporating inner and outer bellows with enhanced isolation. Proper thermal and acoustic insulation helps maintain climate control efficiency, reducing energy consumption while ensuring passenger comfort. Achieving this without increasing the total system weight is a major engineering challenge: our bellows weigh around 300 kg, so adding additional material for improved isolation requires careful design to remove 30–40 kg elsewhere in the system.

Lighting is another area of focus. LED lighting inside the bellows area addresses traditionally dark zones, improving visibility and adding aesthetic and functional value.

How does JOST approach cybersecurity in articulated bus systems?

We are developing our own Articulation Control Unit (ACU) with embedded cybersecurity measures. The development is done in two layers: functional system development and cyber protection. We partner with software companies experienced in cybersecurity to accelerate the process and ensure that our ACU meets customer requirements for data safety.

As you haven’t been exhibiting at Busworld, are there plans to showcase your bus articulation systems in Europe, maybe in some trade events next year?

We are considering a permanent showroom at our Neu-Isenburg headquarters to present new products and developments to end customers. This allows engineers to directly demonstrate products in a flexible and accessible setting. In addition, next year is IAA year, at which JOST will present its comprehensive portfolio in the transport sector.

Supply chain management remains a key challenge (and element for competition) in Europe, particularly regarding delivery timing and ongoing bottlenecks. Could you describe how your supply chain is structured and where it is located, and how it supports timely vehicle production and delivery?”

As a new supplier in the bus market, we need to be technically competitive and cost-effective. We have established long-term partnerships within our supply chain to meet cost targets without compromising quality. This ensures we can compete effectively both technically and commercially.