Kiepe to present its new eDrive at Busworld, integrating inverter and ECU with VEM-made e-motor

At Busworld Europe 2025 Kiepe Electric is putting the spotlight on its new eDrive unit, an integrated system built around the Kiepe Traction Inverter, the Energy Control Unit and an electric motor supplied by VEM. The eDrive Unit will se its operational debut in the new BMC Procity+ EV series, also to be showcased in […]

At Busworld Europe 2025 Kiepe Electric is putting the spotlight on its new eDrive unit, an integrated system built around the Kiepe Traction Inverter, the Energy Control Unit and an electric motor supplied by VEM. The eDrive Unit will se its operational debut in the new BMC Procity+ EV series, also to be showcased in Brussels.

Kiepe to launch eDrive Unit at Busworld

Kiepe describes the Traction Inverter as the technological heart of the vehicle, a component designed for high torque dynamics, low energy consumption and strong climbing ability. According to the company’s own technical sheet, the unit achieves efficiency levels close to 98 percent, operates across a voltage range of 500 to 800 volts, and is packaged in a compact 25-kilogram housing with IP6K9K protection and water cooling.

The BMC Procity+ 12 EV and 18 EV buses, both using the Kiepe eDrive Unit, reach up to 490 kilometres of range and can accept charging powers of 400 kilowatts, results confirmed in the standardized E-SORT energy consumption cycle. The integration of the Energy Control Unit is equally important, since it regulates auxiliaries such as heating and air conditioning in real time and reduces the overall energy demand of the vehicle.

Kiepe eBus HPC Platform at Busworld

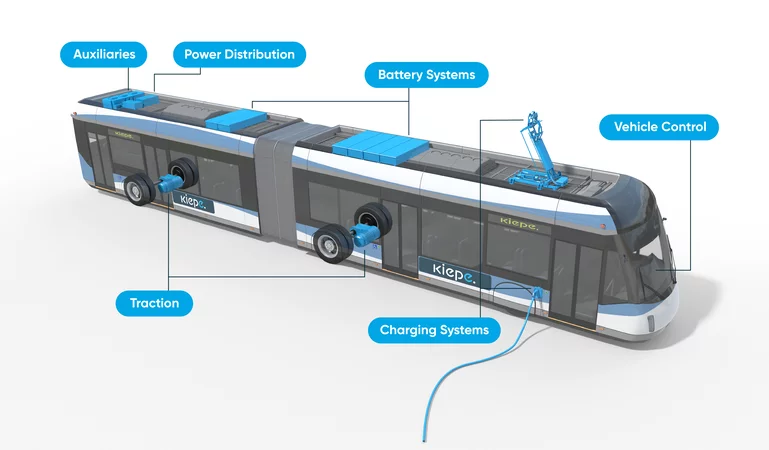

The same traction core also underpins the company’s modular eBus HPC platform, a scalable architecture that extends from standard twelve-metre buses to double articulated vehicles of thirty-six metres.

It comprises six modules that can be adapted and integrated individually or as a complete system: Traction, Power Distribution, Auxiliary Power Supply (APS), Battery Systems, Charging Systems and Vehicle Control. These components can be tailored to the unique requirements of each customer.

The eBus HPC powertrain platform offers two key applications: one for new electric buses and the other for upgrading electric buses to trolley buses using IMC® technology. Kiepe implements both.

The platform achieves charging power of up to 810 kW and short charging times, enabling 24/7 operation. The high charging power allows the installation of smaller batteries. Complemented by cybersecure systems and AI-based fleet management software, the platform ensures an intelligent, safe, and future-proof overall system.

The Trolley Bus Upgrade Package enables the conversion of a standard battery-electric bus into a trolley bus with In Motion Charging (IMC®) technology, Kiepe underlines. Just two additional components, the KIEPE Isolating Converter (KIC) and KIEPE Smart Current Collector (KSC), create the connection between classic battery bus technology and overhead lines and enable flexible mixed operation.

Ulrich Lauel, Vice President Global Sales Systems at Kiepe Electric, says: “The market demands energy-efficient electric bus concepts, and that’s what we deliver. Our collaboration with BMC shows how our traction expertise is being successfully implemented in electric buses. Our modular eBus HPC Powertrain platform also opens up numerous options for new and existing vehicles, transforming the challenge of e-mobility into a real opportunity for the future. We provide our customers with reliable support throughout the entire life cycle of their vehicles.”