UITP Summit 2025, MAN aims at launching a fully driverless bus in 2030 and integrates new battery packs on the city bus range

At the UITP Summit 2025 in Hamburg, MAN Truck & Bus is placing the spotlight vehicle automation and a new generation of home-made battery packs for electric buses. MAN Truck & Bus has set an ambitious goal: launching a fully automated city bus by 2030. According to the manufacturer, this initiative is grounded in years […]

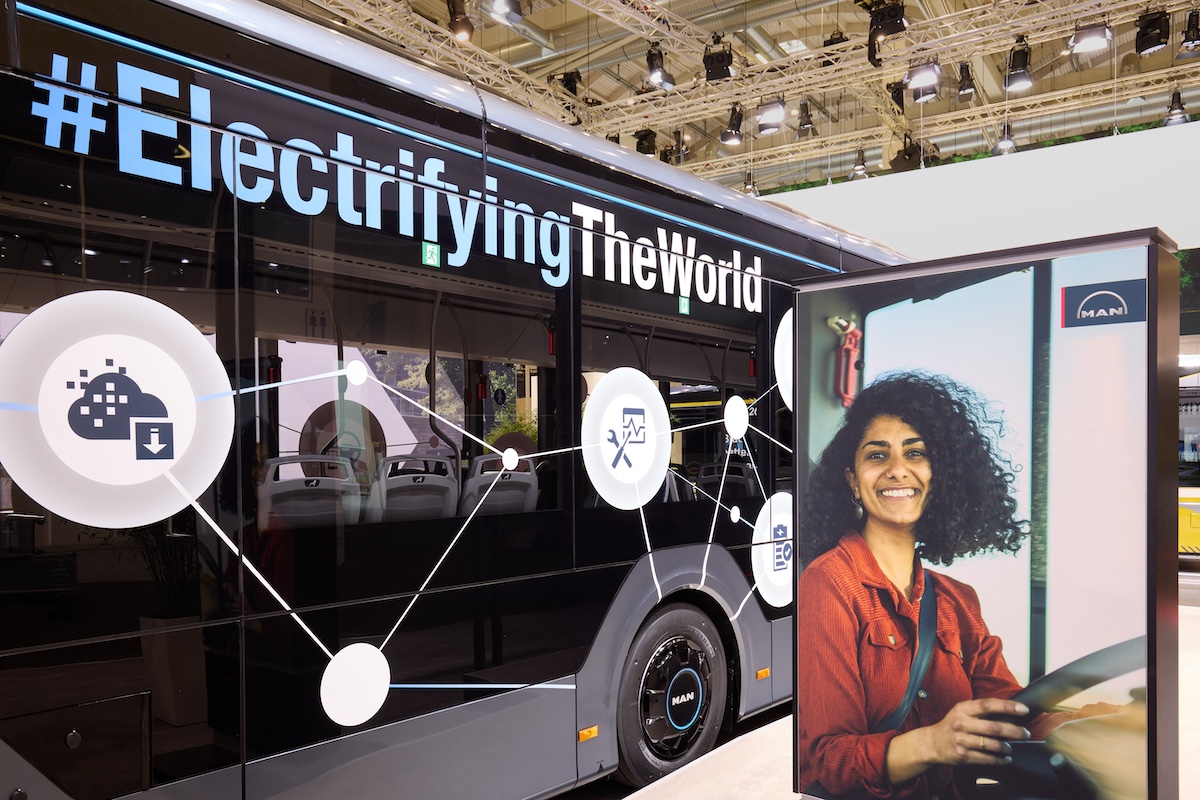

At the UITP Summit 2025 in Hamburg, MAN Truck & Bus is placing the spotlight vehicle automation and a new generation of home-made battery packs for electric buses.

MAN Truck & Bus has set an ambitious goal: launching a fully automated city bus by 2030. According to the manufacturer, this initiative is grounded in years of research and real-world testing through collaborative projects with public and private partners.

Market demand is growing. In Q1 2025 alone, MAN sold 283 electric city buses in Europe, accounting for more than 50% of its total city bus sales on the continent. Since the 2019 launch of the Lion’s City E, over 2,500 units have been sold, covering more than 100 million kilometers without emissions, according to the company.

MAN: a journey towards autonomous driving

A key example is the MINGA research project in Munich, which MAN describes as a cornerstone in its automation roadmap. As part of MINGA (Munich’s Automated Local Transport), MAN is providing an electric Lion’s City E bus equipped with an Automated Driving System (ADS). The pilot operation—scheduled to begin in 2026—will test the bus in real traffic conditions with a safety driver on board. According to the company, special attention is being given to the integration of ADS and electronic systems, made easier by a new electronic platform introduced in the 2024 model year.

MINGA builds on earlier initiatives such as the @CITY project, where MAN and 14 partners focused on automating bus-specific maneuvers like approaching bus stops. Another ongoing project is BeIntelli in Berlin, where an automated MAN electric bus equipped with 60 sensors is being tested along a central route between the Brandenburg Gate and Adenauerplatz. According to MAN, the bus also serves an educational purpose, helping to visualize the technologies and decisions behind autonomous driving.

Automation, according to Michael Roth, Head of Product Strategy Bus at MAN Truck & Bus, is not just a technological endeavor but a response to systemic pressures: “Autonomous buses could help to address this issue and further improve connections in cities, conurbations and rural areas.”

Looking ahead, MAN says it plans to test automated buses in different markets and use cases, gradually refining the systems and preparing them for commercial deployment. Achieving SAE Level 4 automation will require redundancies in all safety-critical systems—ADS, braking, steering, and communication—according to the company. The ultimate objective is to enable driverless operation in defined areas.

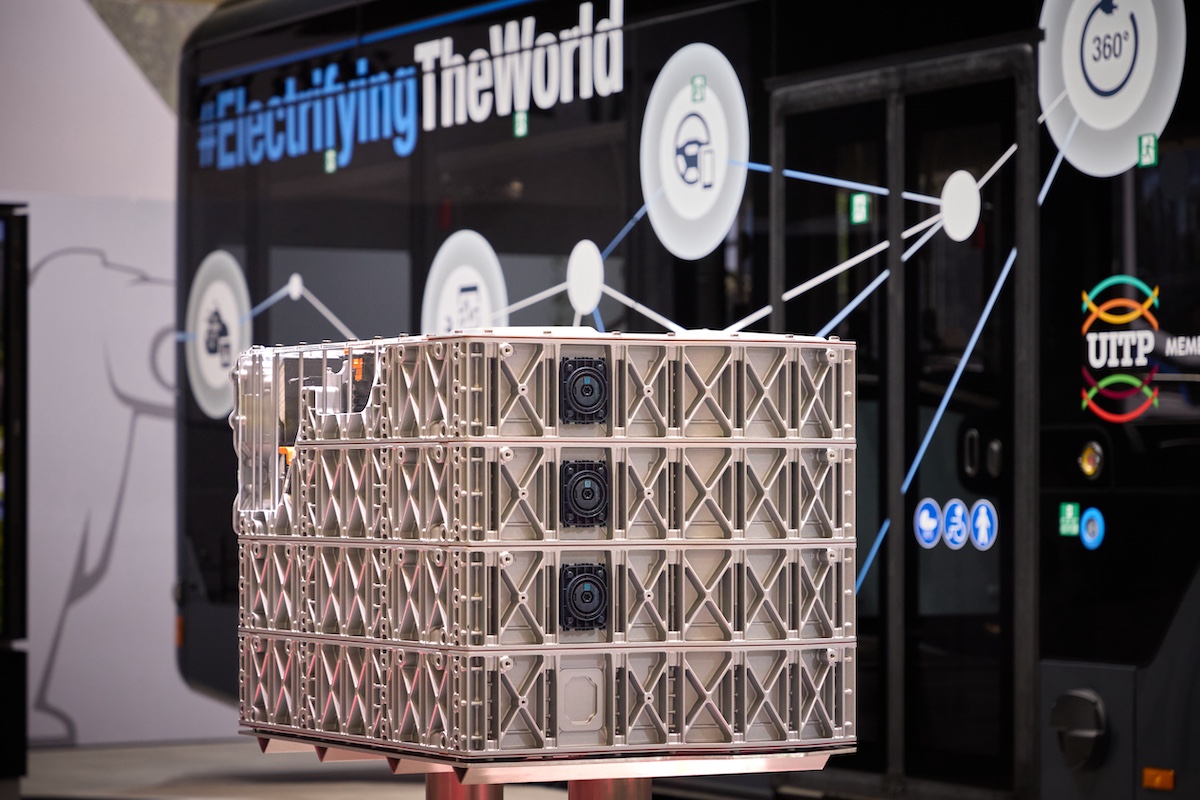

MAN battery packs on the Lion’s City E range

On the electric mobility front, MAN is unveiling a major product update for its Lion’s City E bus family. The 2025 model year introduces a new generation of lithium-ion batteries (NMC technology), produced in-house at the company’s Nuremberg plant.

These batteries, according to MAN, are more powerful, lighter, and more compact than their predecessors. According to the manufacturer, these batteries offer higher energy density, improved safety features, and reduced weight, resulting in enhanced efficiency and operational flexibility. The modular configuration allows operators to tailor the number of battery packs to match route and capacity requirements.

At launch, the 12-meter Lion’s City E will be available with four or five packs (356 or 445 kWh), and the articulated 18-meter version with six or seven packs (534 or 623 kWh). Future variants with six (solo) and eight (articulated) packs are also planned. The 10-meter version will be fitted with four packs (356 kWh).

Two battery usage strategies are offered. According to MAN, the “Maximum Range” strategy allows daily ranges up to 380 km, with up to 90% discharge. The “Reliable Range” strategy prioritizes battery longevity, starting with a 65% discharge depth and increasing over time to ensure consistent range over the vehicle’s life.

According to MAN, the new battery system supports a service life of up to 14 years and one million kilometers. The production process in Nuremberg is designed to be energy-efficient and resource-conserving. Thanks to an established recycling process, up to 96% of the battery components can be recovered.