Ballard to launch new fuel cell engine (9th generation) at Busworld Europe 2025

As the most widely deployed range of fuel cells for buses globally, Ballard Power Systems’s FCmove® engines for medium- and heavy-duty mobility now power more than 2,250 zero-emission buses across the world, logging over 200 million kilometres of on-road operational experience – with a 99% availability rate for transit operators, according to Ballard. The company will unveil its ninth-generation fuel cell module – designed specifically for transit buses to lower lifecycle cost – at Busworld Europe 2025 in Brussels from 4–9 October.

This content belongs to the series Busworld Spotlight, offering a dedicated space to companies presenting their vision, products, strategies and innovative solutions in the run-up to Busworld Europe 2025, from October 4–9 in Brussels, Belgium – and beyond.

Ballard Power Systems is exhibiting in Hall 9, Stand 957.

As the most widely deployed range of fuel cells for buses globally, Ballard Power Systems’s FCmove® engines for medium- and heavy-duty mobility now power more than 2,250 zero-emission buses across the world, logging over 200 million kilometres of on-road operational experience – with a 99% availability rate for transit operators, according to Ballard.

In Europe, Ballard holds an 80% market share in fuel cell bus engines with over 850 vehicles deployed across more than 30 cities on the continent.

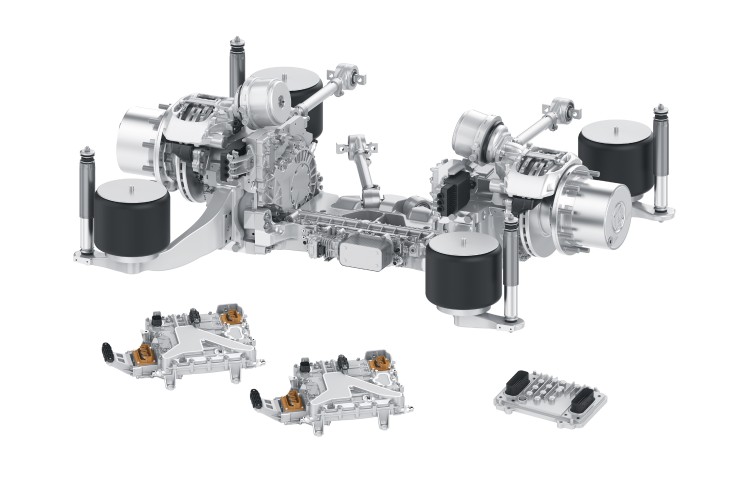

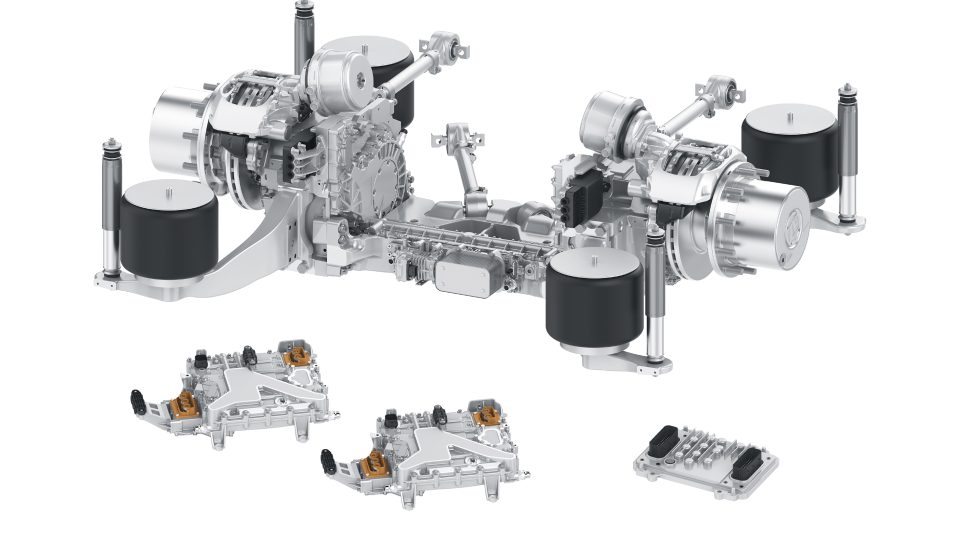

Ballard’s mature FCmove®-HD and FCmove®-HD+ modules have been integrated into thousands of transit applications and validated through tens of millions of service kilometres globally. Purpose-built for public transit vehicles, the 70kW and 100kW engines set the benchmark for decarbonized transport.

Ballard new fuel cell bus engine is ready for Busworld

Ballard’s FCmove® platform enables lower cost, simplified vehicle integration, and smarter fleet services, with unmatched product performance and robust design laying the foundation for the next generation of fuel cell innovation.

That pioneering technology is now here, and Ballard is excited to unveil its ninth-generation fuel cell module – designed specifically for transit buses to lower lifecycle cost – at Busworld Europe 2025 in Brussels from 4–9 October.

A fuel cell engine designed for public transport buses

“Ballard’s new fuel cell engine is the latest innovation on the company’s new core product platform which anchors broader advances targeting the industry’s fundamental challenge: narrowing the gap in cost of ownership parity with legacy diesel systems,” said David Mucciacciaro, Senior Vice President and Chief Commercial Officer, Ballard. “The fuel cell design significantly reduces integration complexity for bus manufacturers while improving life-time cost and performance for transit operators.”

Ballard’s next-generation fuel cell engine for zero-emission public transport is engineered specifically for transit bus duty, complete with new design, architecture, and component subsystems – creating a more cost-effective product through to the vehicle’s end-of-life.

Enhancements for bus manufacturers and operators include, in the company’s words, “30% increase in system power (end-of-life) with improved durability, operating and freeze-start temperatures and higher power density, 25% increase in volumetric power density through integrated DC/DC packaging, 25% higher maximum radiator outlet temperature (60°C → 75°C), simplifying vehicle thermal management, 40% reduction in total part count”.

The zero-emission engine targets a peak power capability of at least 75kW, and subsystems support an expected service life of approximately 25,000 operating hours under standard transit duty cycles.

With a module built on Ballard’s proven FCmove® proprietary product technology – the company’s latest fuel cell is designed to deliver greater sustained power, simplify vehicle integration, improve in-service performance, and reduce lifecycle costs as part of Ballard’s roadmap toward diesel parity.