BSPL: partner of the OEMs in the transformation towards efficient electromobility

Authored and sponsored by BSPL. The company is exhibiting at Busworld Europe 2025, Hall 6, Stand 652b Temperature management is one of the key elements of modern electromobility. The efficiency of cooling and heating systems determines the safety, performance, and durability of electric vehicles. In this area, BSPL – a Polish company with over 35 […]

Authored and sponsored by BSPL.

The company is exhibiting at Busworld Europe 2025, Hall 6, Stand 652b

Temperature management is one of the key elements of modern electromobility. The efficiency of cooling and heating systems determines the safety, performance, and durability of electric vehicles. In this area, BSPL – a Polish company with over 35 years of experience – is increasingly strengthening its position by developing comprehensive solutions for OEMs and fleet operators.

Each year, BSPL delivers more than 25,000 units, with projects carried out both in Europe and the USA. The company continuously expands its portfolio – recently also starting work on systems for trams and trolleybuses, addressing the growing needs of cities committed to zero-emission transport.

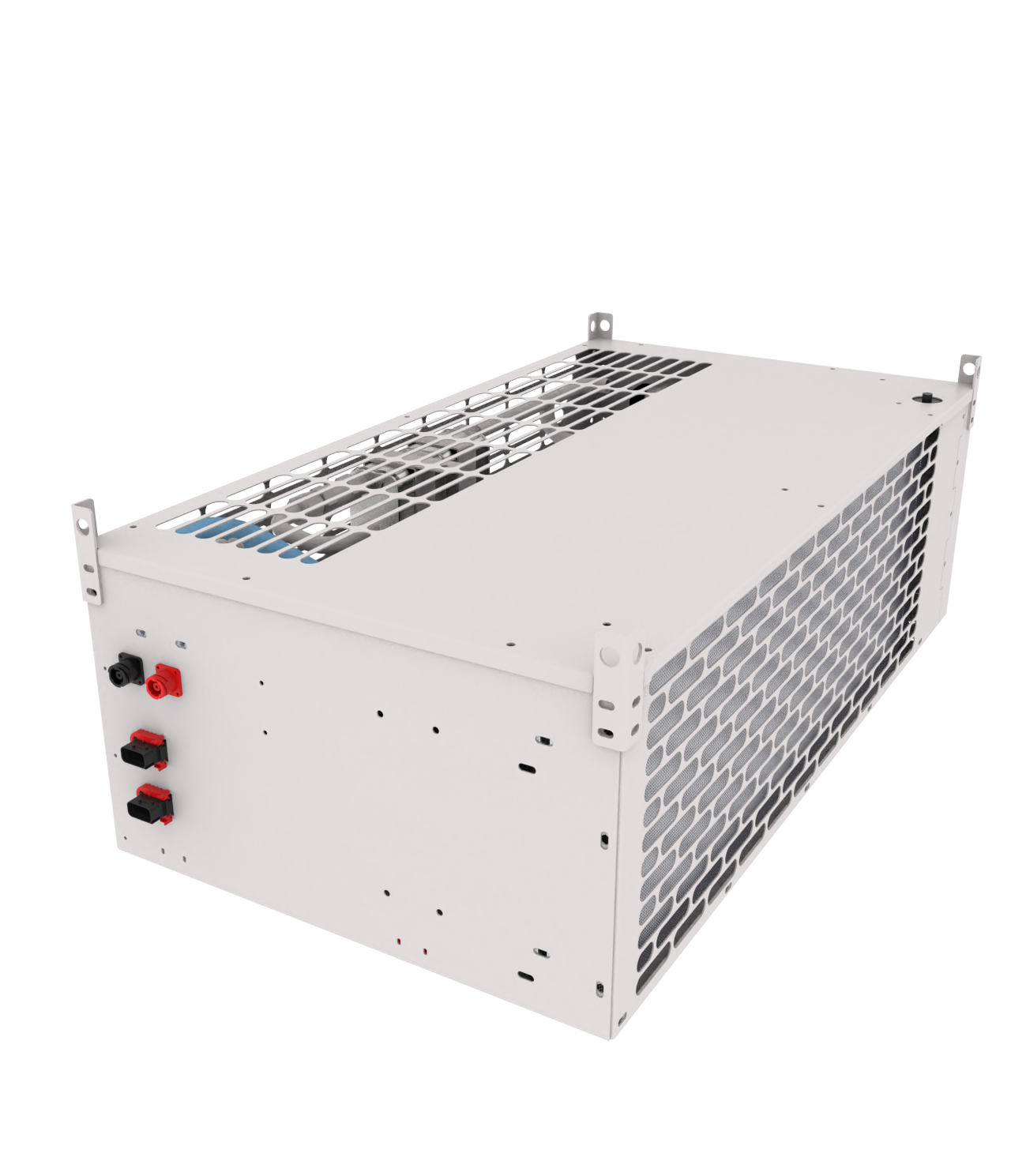

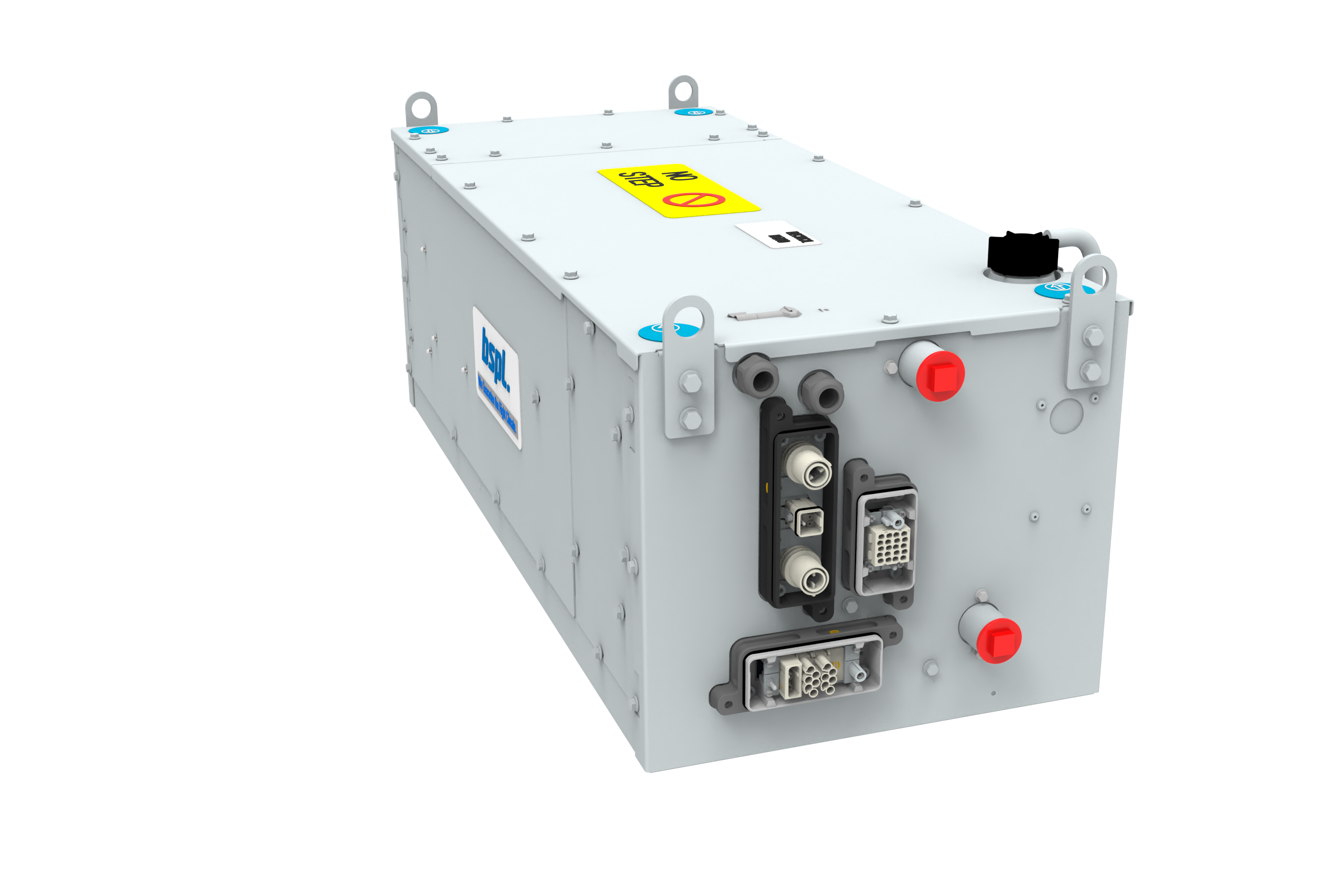

At the Busworld Europe 2025 trade fair in Brussels, BSPL will present its flagship AC10 and AC09 systems along with a broader portfolio of solutions for electric, hydrogen, and hybrid vehicles.

Partnership-based design: from concept to implementation

What sets BSPL apart is the way it works with clients. From the very beginning, the company engages in creating entire systems, not only delivering components but also co-designing solutions.

“Together with our clients, we analyze possible operating scenarios and system topologies to find the optimal solution. Our interdisciplinary team can very quickly modify an existing project or create a new solution tailored to a specific application. Thanks to this, OEMs gain a real time and cost advantage,” says Tomasz Turek, CTO of BSPL.

The company has its own software department and full control over metal production, which ensures high flexibility in adapting solutions. A prototype of a new system often reaches the client in just three months.

To meet rising demand, BSPL is investing in infrastructure development. In Poland, a new facility dedicated to systems for electric vehicles is being established.

The company is also strengthening its global presence. Recently, BSPL opened a location in the United States, initially serving as a service center, but soon also becoming a production plant for customers in this market.

“The U.S. market is a huge opportunity for us. We are already implementing our first projects there and see significant interest in our solutions. This is just the beginning, but early successes show that our partnership-driven approach is also valued outside Europe,” comments Robert Felchner, Sales Director of BSPL.

AC10 and AC09: flagship systems for electromobility

BSPL focuses on delivering solutions that meet the most demanding market needs:

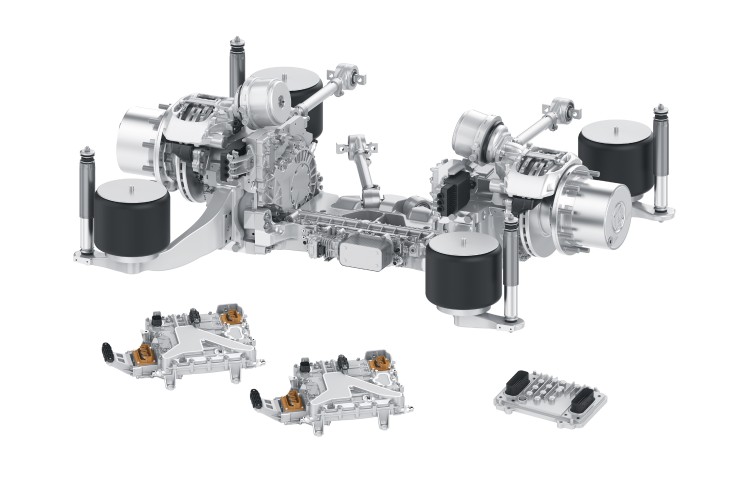

AC10 is an integrated thermal management system for the entire powertrain, from batteries to inverters and converters. It simplifies integration, reduces the number of components, and extends vehicle range, while ensuring reliability even in harsh conditions.

AC10 was designed for large bus platforms that operate for many hours daily. For manufacturers, this means the ability to implement one scalable solution across different vehicle models – from 12-meter city buses to 18-meter articulated buses. As a result, OEMs reduce design costs and can introduce new vehicle generations faster.

For fleet operators, operational benefits are key: intelligent cooling mode switching reduces energy consumption, directly translating into longer range and lower operating costs. Moreover, AC10 ensures high durability and stable performance – even after one million kilometers over a bus’s lifetime.

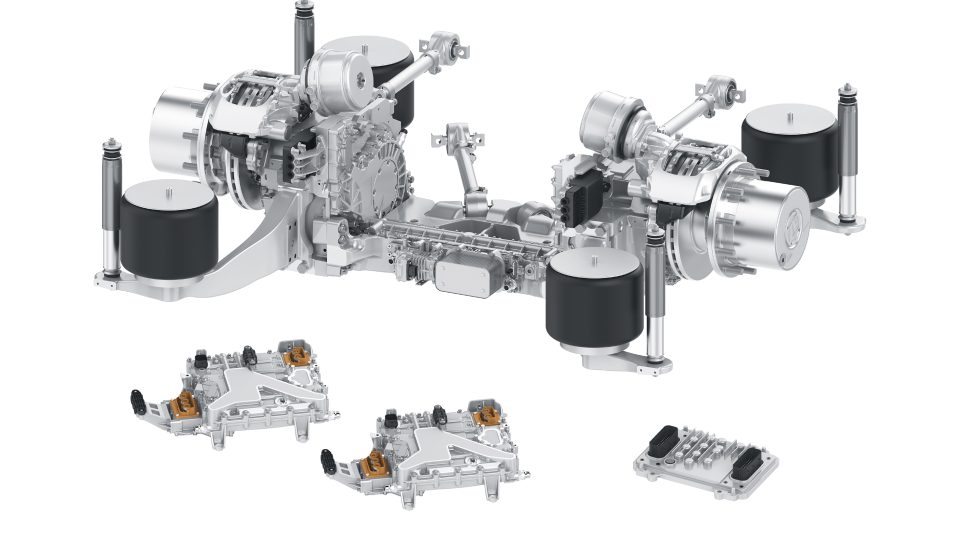

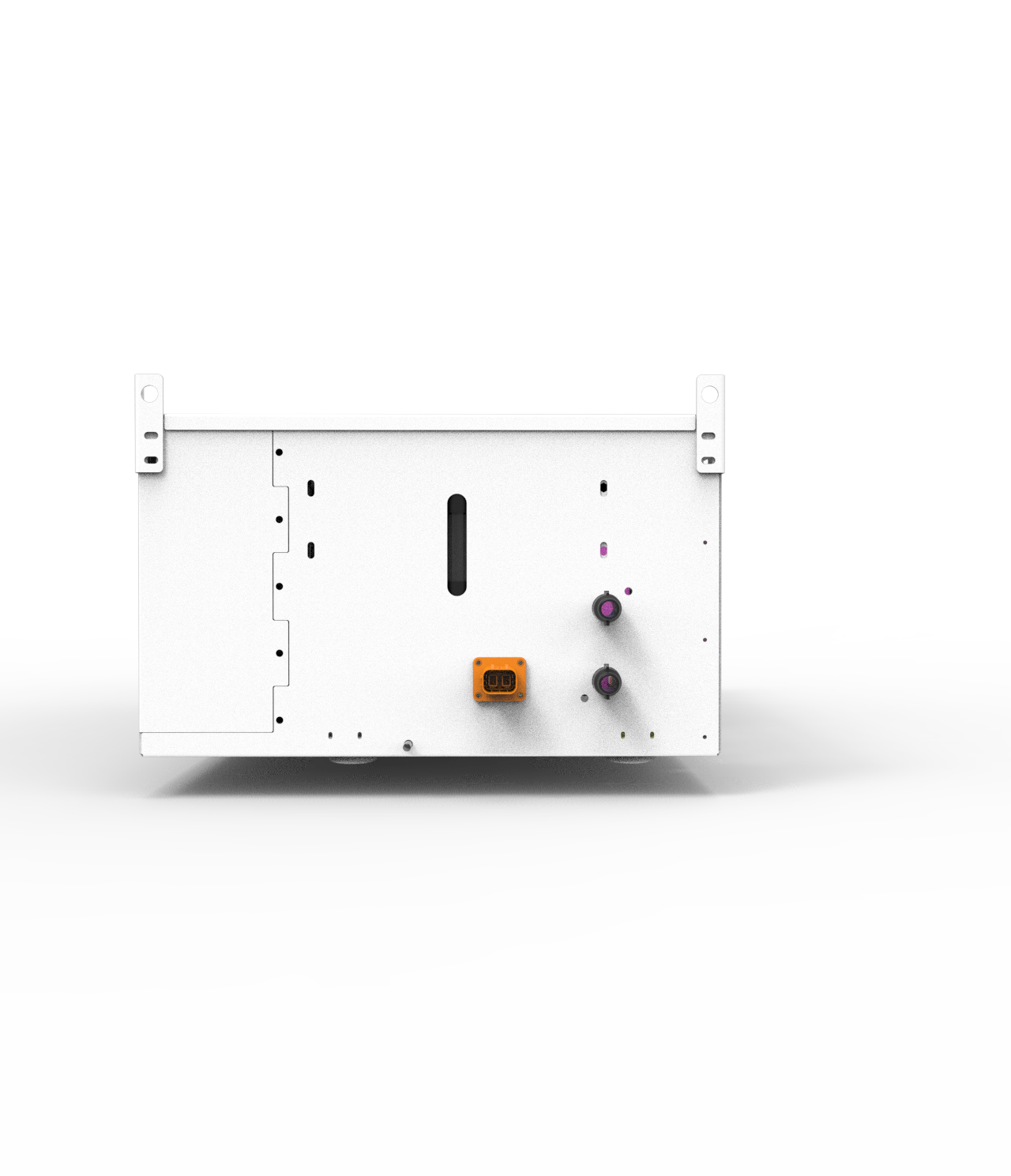

The AC09, on the other hand, is a compact system for smaller platforms such as trolleybuses, minibuses, and shuttles. Its simple integration and reliable operation across a wide temperature range allow manufacturers to bring new vehicles to market faster.

AC09 is particularly valued by customers who need a lightweight yet dependable solution. For manufacturers, it means easier design of compact vehicles – the system requires little space and, thanks to its Plug&Play architecture, shortens integration time.

From the operators’ perspective, AC09 above all guarantees reliability. Vehicles equipped with this system perform well both in dense city traffic and in less predictable conditions, such as shuttle operations or short, high-dynamic routes. An additional benefit is lower servicing and maintenance costs – the system requires minimal upkeep, helping fleets maintain high vehicle availability.

“AC10 and AC09 reflect our approach – different products for different segments, but with a shared philosophy: efficiency, simplicity, and durability in operation. These solutions provide our customers with a competitive edge – both in terms of cost and implementation time,” emphasizes Turek.

BSPL offers a complete portfolio – from electronics to fuel cells

BSPL’s broad portfolio includes:

- cooling systems for inverters, traction motors, and DC/DC converters,

- systems for on-board chargers,

- systems for fuel cells,

- as well as proven solutions for diesel and hybrid engines.

This allows the company to offer OEMs a consistent ecosystem of thermal solutions – from light vehicles to large buses and rail transport.

Technologies that reduce energy costs, by BSPL

BSPL also develops technologies that help fleet operators reduce energy costs. By utilizing the side effects of system operation, the company enables customers to achieve energy savings of up to 30%, which directly translates into longer vehicle range and lower operating costs.

“Energy savings are a tangible business value for operators. Thanks to our solutions, they can make better use of their fleet and increase its efficiency,” notes Turek.

BSPL is preparing to obtain IATF 16949 certification, a key quality standard in the automotive industry. The certification is planned for next year and will be another step in strengthening the company’s position as a trusted partner for global manufacturers.