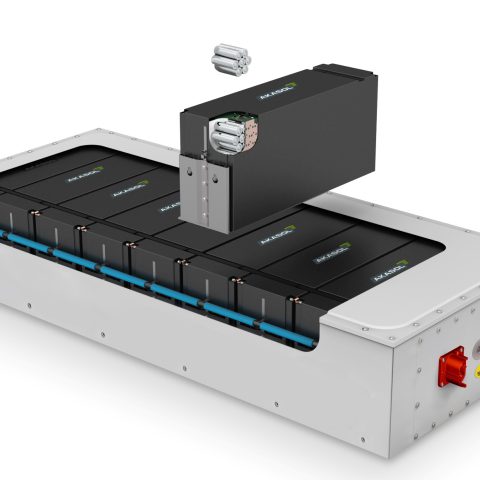

Here is the new AKASystem AKM CYC ultra-high energy battery system from Akasol

A new ultra-high energy battery system for long distance applications. Akasol presents the third generation of battery systems, namely the new AKASystem 9 AKM 150 CYC, with the highest energy density available on the market. This makes the system particularly suitable for all-electric long-distance applications such as buses or trucks. It has a rated energy […]

A new ultra-high energy battery system for long distance applications. Akasol presents the third generation of battery systems, namely the new AKASystem 9 AKM 150 CYC, with the highest energy density available on the market. This makes the system particularly suitable for all-electric long-distance applications such as buses or trucks. It has a rated energy of just under 100 kWh, which can be scaled up as required with different systems. The ultra-high energy battery system will be produced at the Gigafactory 1 in Darmstadt from 2023.

«With our third-generation battery system, we are once again underlining our technological leadership. The high gravimetric energy density in the same space as the predecessor system leads to significant efficiency improvements and an increased range. At the same time, it is a particularly cost-efficient battery system that offers flexible scaling options depending on the area of application», said Sven Schulz, Ceo of Akasol.

With a nominal energy of 98 kWh and a continuous charge rate of 1 C, the AKASystem 9 AKM 150 CYC enables a maximization of the range by up to 50 percent compared to conventional systems on the market, with simultaneous HPC capability. Thanks to the rapid charging capability (opportunity charging) and with charging processes during longer standstill times, for example overnight (depot charging), the use of the system can be flexibly designed, and the service life of the battery cells is optimized. A service life of up to 4,000 charging cycles is achieved, which makes the lithium-ion battery system an extremely long-lasting system.

Highest safety requirements

The active liquid cooling with a water-glycol mixture and the good thermal insulation of the battery system makes it possible to operate the cells in the ideal temperature range and achieve an associated improvement in performance with less ageing. The system design includes multiple safety features, such as two separate CPU cores to increase fail-safety. The AKASystem 9 AKM 150 CYC also has IP67 and IP6K9K protection classes, high fire protection and is developed according to the industry standard ISO 26262.

By using battery cells in the 21700-standard format, Akasol benefits from the further development of the cells which is independent of the battery system. This also benefits future products, so that the energy density will be continuously increased in the coming years without adapting the system architecture. In addition to the increase in efficiency and cost savings, the use of standard cells also enables a high availability of battery cells through various manufacturers with global production facilities.

«The AKM CYC platform enables customized development for each application. We check the detailed properties with the help of customer-specific simulations. Production of the new AKASystem 9 AKM 150 CYC ultra-high energy battery system will start next year in our Gigafactory 1 in Darmstadt. This will be followed by our plant in Hazel Park, USA, in the course of 2023», says Holger Dilchert, Head of Sales On-Highway at Akasol.

The highly automated and fully networked production in Gigafactory 1 in Darmstadt already has 1 GWh of installed production capacity and will be increased to 2.5 GWh in the course of 2022. Depending on customer demand, it can be expanded to 5 GWh in Darmstadt in the future. In Hazel Park, the production capacity will be increased to 2 GWh by 2023. Akasol will thus be able to significantly increase the production of lithium-ion battery systems for commercial vehicles on both continents in the near future.

AKASOL will present the new high-energy battery system AKASystem AKM CYC in the coming days at the Battery Show Europe from 30 November to 2 December 2021 in Stuttgart.