Iveco Group inaugurates FPT Industrial’s e-powertrain plant in Turin

It will be the first zero-emission production site. It will be the new e-powertrain plant in Turin. We are talking about Iveco Group‘s inauguration of the plant-under the brand name of FPT Industrial, the global powertrain brand of Iveco Group-which is entirely dedicated to the production of its range of electric powertrains. Covering a total […]

It will be the first zero-emission production site. It will be the new e-powertrain plant in Turin. We are talking about Iveco Group‘s inauguration of the plant-under the brand name of FPT Industrial, the global powertrain brand of Iveco Group-which is entirely dedicated to the production of its range of electric powertrains.

Covering a total area of 15,000 square meters, the site generates its own energy with solar panels and other innovative photovoltaic and wind technologies, purchases additional energy from renewable sources, and purchases carbon credits to fully offset its CO2 emissions. A 6,000-square-meter indoor space planted with 100 drought-resistant plants adds an additional expected CO2 absorption of about seven tons per year.

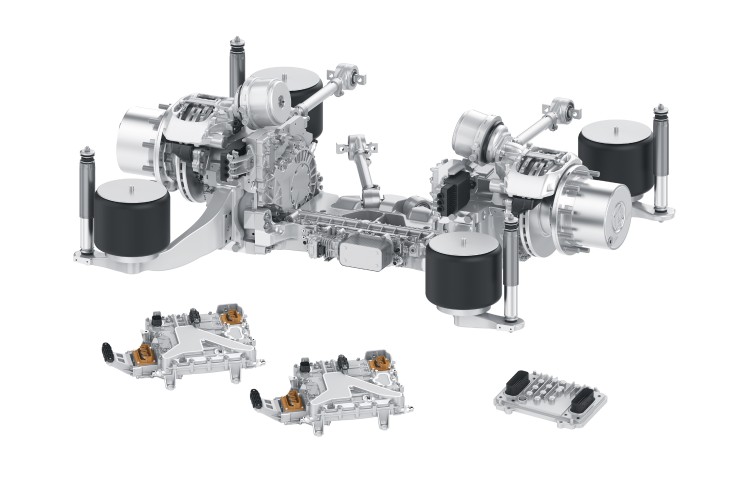

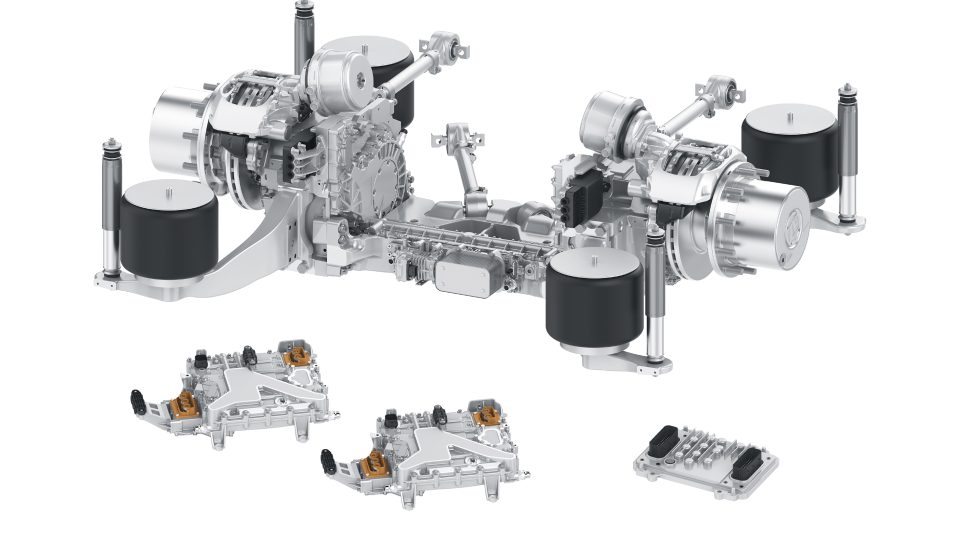

At full capacity, the plant will employ about 200 people to produce more than 20,000 electric axles and as many battery packs per year.

The electric axles will equip heavy vehicles such as the Nikola Tre truck, while the electric transfer boxes and compact battery packs will be installed in light commercial vehicles and minibuses, such as the new Iveco eDaily. Both of these zero-emission vehicles were unveiled a month ago at the IAA Transportation fair in Hannover, Germany.

The adoption of Industry 4.0 technologies-including highly automated warehouses, augmented and virtual reality, smart sensors, 3-D scanners for metrology-level measurements, 3-D reality simulators, cooperative robots, and thermo-cameras-will ensure improved safety, sustainability, quality, productivity, and logistics management.