Konvekta supplies 60% of German e-buses with CO2 technology

60% of German e-buses drive with Konvekta CO2 technology. The figure is outlined by the supplier itself. The use of electric heaters proved to be a real energy guzzler for e-buses, as widely known. To generate one kWh (kilowatt hour) of heating energy, the system needs 1.1 to 1.23 kWh of energy from the battery, […]

60% of German e-buses drive with Konvekta CO2 technology. The figure is outlined by the supplier itself.

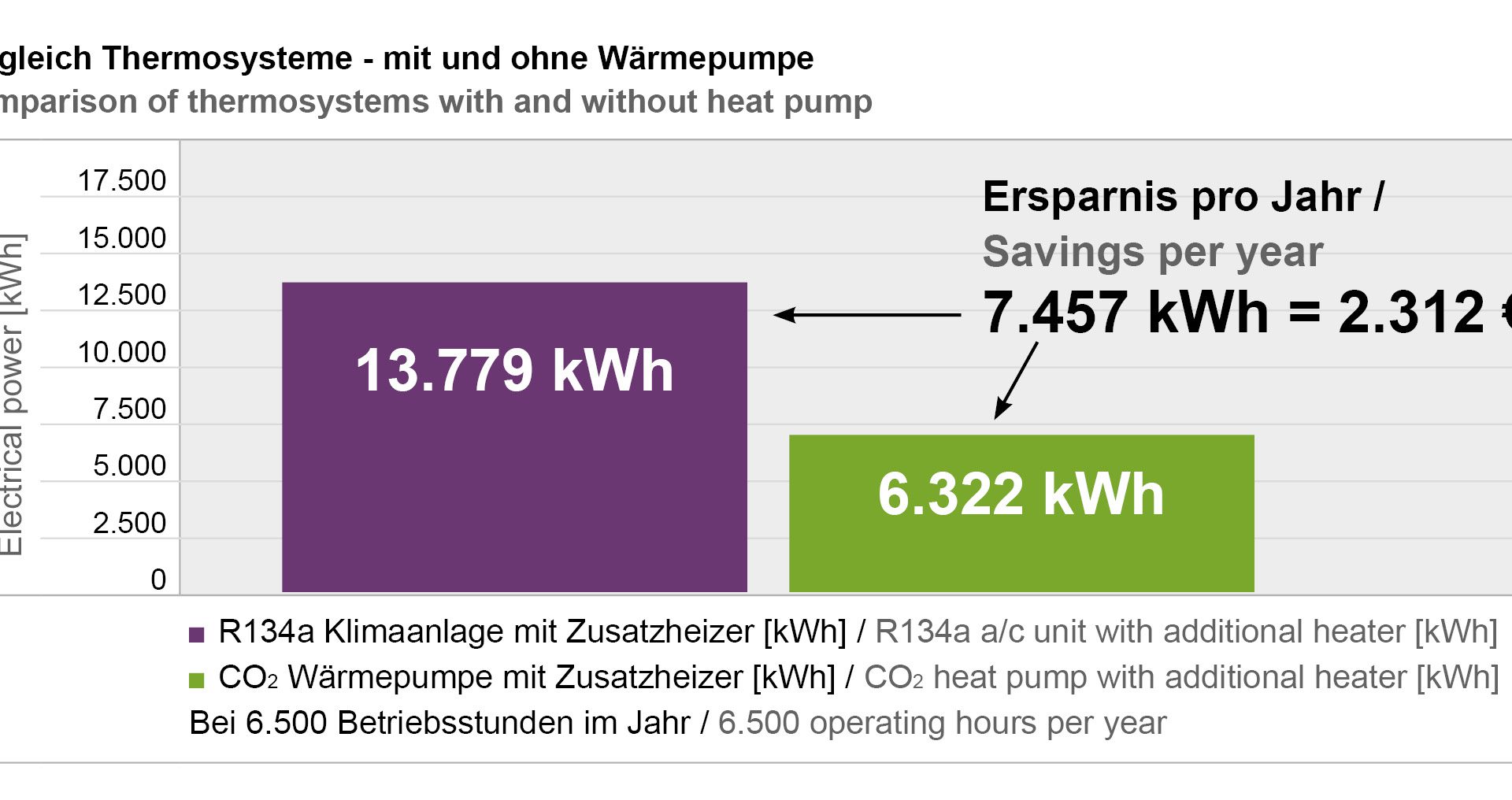

The use of electric heaters proved to be a real energy guzzler for e-buses, as widely known. To generate one kWh (kilowatt hour) of heating energy, the system needs 1.1 to 1.23 kWh of energy from the battery, the supplier says. Many transport companies and bus manufacturers proved in several field- and daily use measurements that the already limited energy supply was reduced to such an extent that the range even decreased temporarily by more than 50%.

What is interesting, Konvekta says, “in 2021 over 60% of German transport companies decided for a Konvekta CO2 heat pump system. Depending on the vehicle, at -10°C outside temperature, the CO2 heat pump requires around 45 kWh, compared to conventional electric heating components, which require more than 110 kWh per 100 km“.