The advantages of using stainless steel in bus structures. A study by supplier Outokumpu with Munich University

Below, a contribution by Stefan Schuberth, Sales Manager Automotive Business Line, Advanced Materials, Outokumpu, Krefeld, Germany; Prof. Dr.-Ing. Klemens Rother, University of Applied Sciences, Munich, Germany; Dr. Werner Pohl, FCMS GmbH, Munich, Germany. Stainless steel manufacturer Outokumpu has carried out a first of its kind project with CAD/CAE solution specialist FCMS, the Munich University of […]

Below, a contribution by Stefan Schuberth, Sales Manager Automotive Business Line, Advanced Materials, Outokumpu, Krefeld, Germany; Prof. Dr.-Ing. Klemens Rother, University of Applied Sciences, Munich, Germany; Dr. Werner Pohl, FCMS GmbH, Munich, Germany.

Stainless steel manufacturer Outokumpu has carried out a first of its kind project with CAD/CAE solution specialist FCMS, the Munich University of Applied Sciences and RotherCONSULT to investigate the advantages of using stainless steel in bus structures.

The results show that using high-strength stainless steel to replace tubular bus frame elements normally manufactured in carbon steel could reduce weight by up to 35 % – over 1,000 kg – while staying cost-competitive.

Why switch to stainless steel?

Traditionally, about 90 % of buses are made of carbon steel. However, stainless steel offers a number of advantages for both bus manufacturers and operators. In particular its corrosion resistance offers sustainability as well as a reduction in maintenance time and cost. Furthermore, high strength stainless steel grades are commercially available that offer enormous weight savings. This is illustrated in the virtual development performed by the project team.

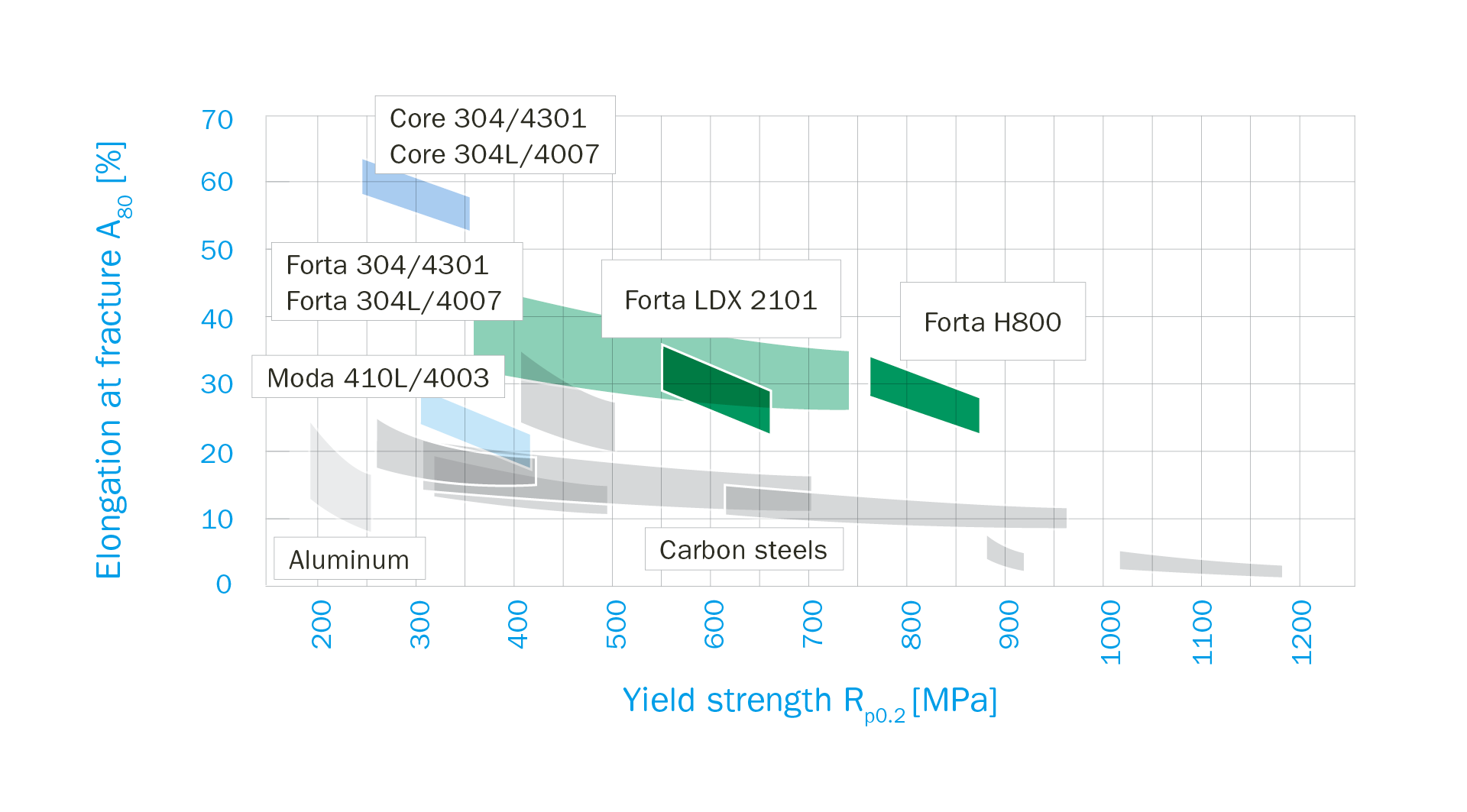

Suitable candidate materials for a tubular bus structure are displayed in Figure 1. Generally, low cost, but non-corrosion resistant, carbon steel is used. Typically the grade is S355 as well as the higher strength S460, with both names referring to their minimum yield strength. The next materials on the list are stainless steels of low strength levels. Finally, there is the high-strength range of stainless steels including lean duplex Forta LDX 2101 that has high corrosion resistance. There is also Forta H800 developed for its high strength capabilities, which is why its corrosion resistance appears low for a stainless steel.

The project focused on assessing the weight and cost benefits of Forta H800 against the S460 carbon steel that offers the most challenging comparison for existing bus structures. The recently developed grade S700 could also be considered that offers a comparable yield strength to Forta H800, but with much lower elongation and crash absorption/impact resistance potential.

Forta H800 for high strength and high impact resistance

Forta H800 is a fully-austenitic stainless steel developed for safety-critical structural vehicle components. It opens up new opportunities in lightweight engineering and design by combining ultra-high strength and very high energy absorption in the event of an impact. It also has the benefit of being nickel-free, removing the price volatility associated with grades that rely on nickel as an alloying element.

A key characteristic of Forta H800 is its TWIP (Twinning Induced Plasticity) strengthening mechanism that causes the material structure to harden continuously when subjected to a crash impact.

With Forta H800 identified as a suitable alternative material, FCMS, the Munich University of Applied Sciences, RotherCONSULT and Outokumpu collaborated to determine how it could be best used in bus structures. The primary aims were to examine how using stainless steel could:

- minimize structural weight

- minimize material and manufacturing costs

- ensure sufficient strength for dynamic (quasistatic) and cyclic loading

- ensure sufficient static and dynamic stiffness

- ensure safety during rollover scenarios

FCMS performed parametric modelling. The university performed fatigue testing on welded tubular joints of the two materials and RotherCONSULT developed and compiled the system requirements, simplified analysis strategies and procedures for structural qualification. Outokumpu supplied the materials, related knowledge and data.

AI-driven approach to simulation

To simulate the performance of the bus structure a combination of tools was used, including parametric geometry modeling as well as fast, automatic and robust analysis methods. AI (artificial intelligence) was used to automatically generate design alternatives and their associated simulation models. It would not have been feasible to undertake this work manually, as it required the evaluation and iteration of thousands of designs.

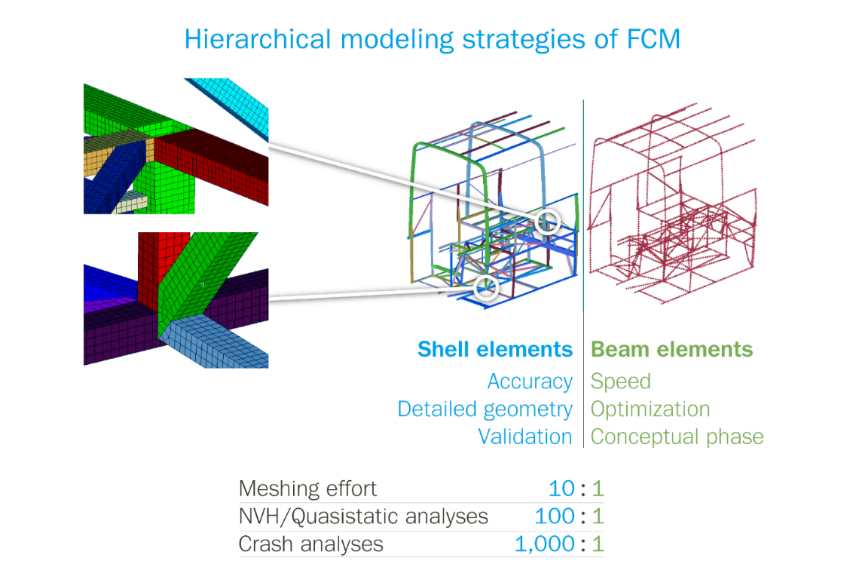

At the heart of the approach was the Fast Concept Modeler (FCM), a tool embedded in CATIA (computer-aided three-dimensional interactive application), a product design and development software package. FCM works with both conceptual beam type models as well as detailed shell and solid models. It offers the capability to evaluate the impact of changes in profiles, wall thicknesses and materials, as well as changes in topology such as the position of frame segments and junctions. This last aspect, which would ultimately result in a re-design of the bus frame, was not part of this project, but offers the potential for further lightweighting in future design exercises.

The project aimed to consider hundreds or even thousands of design alternatives. This required efficient analysis methods, for which beam idealizations are well suited. Once a potentially viable concept was identified, shell element meshing was used to validate its structural integrity or to continue the optimization process with more attention to local details.

FCM can be used to extract both beam and shell meshes simultaneously from the same three-dimensional geometrical CAD model, as highlighted in Figure 2. It also shows the approximate analysis time, with beam meshing around 1,000 times faster than shell meshing for crash analysis without a high loss of accuracy. This can result in massive time savings when steps must be repeated many times.

Simulations of a generic bus design

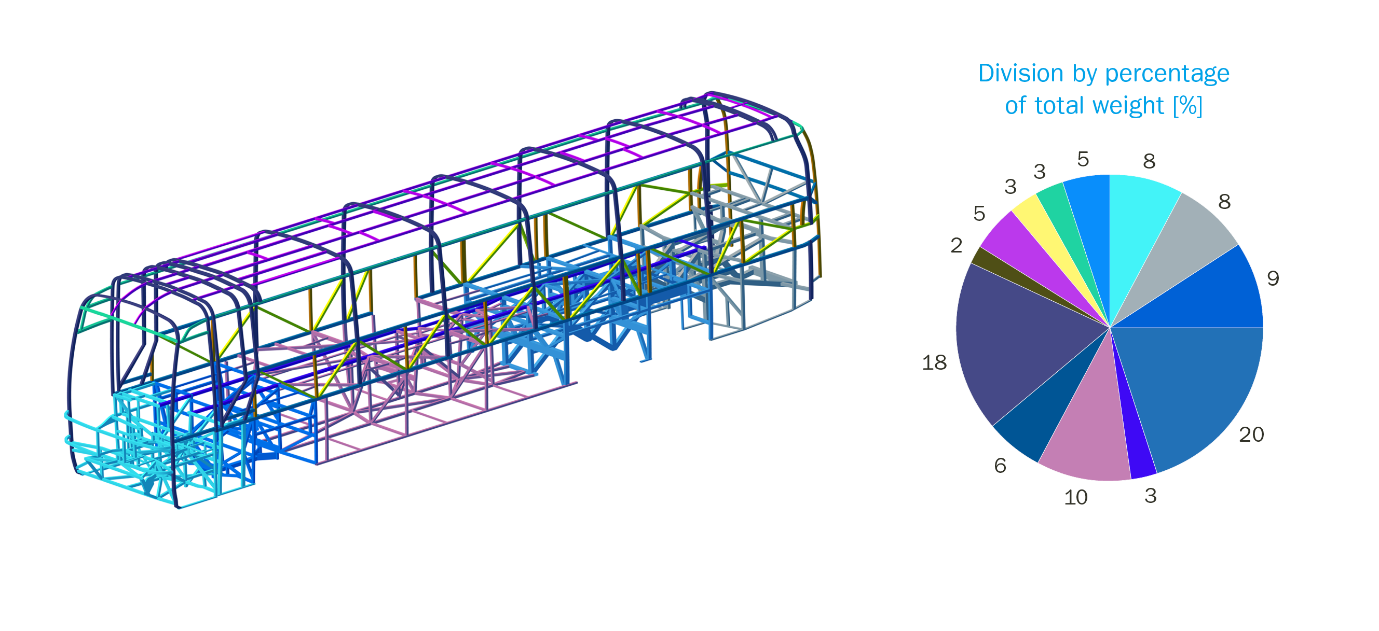

The simulation project was based on a generic reference bus model as shown in Figure 3. The design is built on published representations but is intended to be “typical”, rather than representing a bus from any particular manufacturer. It is around 14 meters in length with three axles, capable of carrying 63 passengers and two drivers, resulting in a total mass of 20,800 kg.

To restrict the number of design variables, the frame members were placed in 13 groups as indicated by the different colors in Figure 3 . The structural members in each group were analyzed simultaneously for each design alternative.

The model was analyzed under the following four load cases, with the two alternative structural materials of carbon steel and stainless steel:

- quasistatic loading

- cyclic loading

- torsional stiffness and NVH (noise, vibration and harshness) – an important factor for passenger comfort and driving dynamics

- rollover for compartment intrusion during a crash

Simulation results

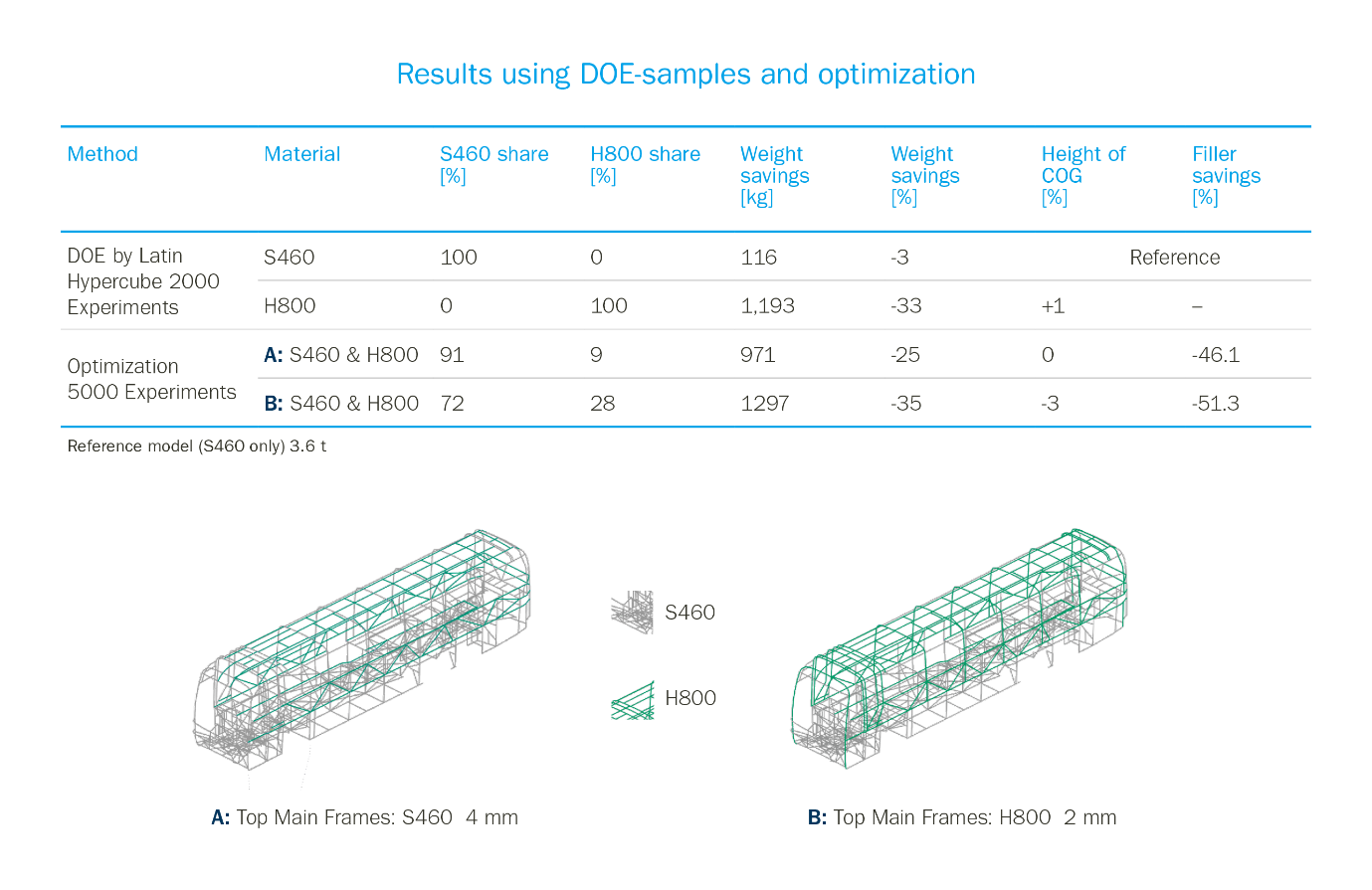

Figure 4 shows the results of the simulations from a very large number (thousands) of experiments.

The reference case is based on a pure frame structure entirely made of carbon steel (S460) with a weight of 3,600 kg. Even in this case, optimization enabled a useful weight saving of 116 kg. With complete substitution of the carbon steel by stainless steel (Forta H800) the mass of the structure was reduced by one third, saving 1,193 kg. A key finding from the rollover simulation was that the wall thickness of the tubing could be reduced from 4 mm to 2 mm, accounting for a large part of the weight saving.

The project then moved on to examine an optimization strategy with a hybrid structure featuring both types of steel. Two alternatives were examined. The first, and most obvious, was to use Forta H800 for the top mainframes. It was also interesting to observe what happens when the top mainframes are built with S460.

The weight reduction compared to the S460-only design is very significant – 25 % if S460 is used for the top mainframes and 35 %, when most of the upper section is created in Forta H800. The potential weight reduction is almost 1,300 kg.

A further significant factor is that the volume of welding required to create the structure is reduced by over 50 %. What is also interesting is that there is a small lowering in the center of gravity (COG), which is beneficial for driving dynamics.

What is the cost of switching to stainless steel?

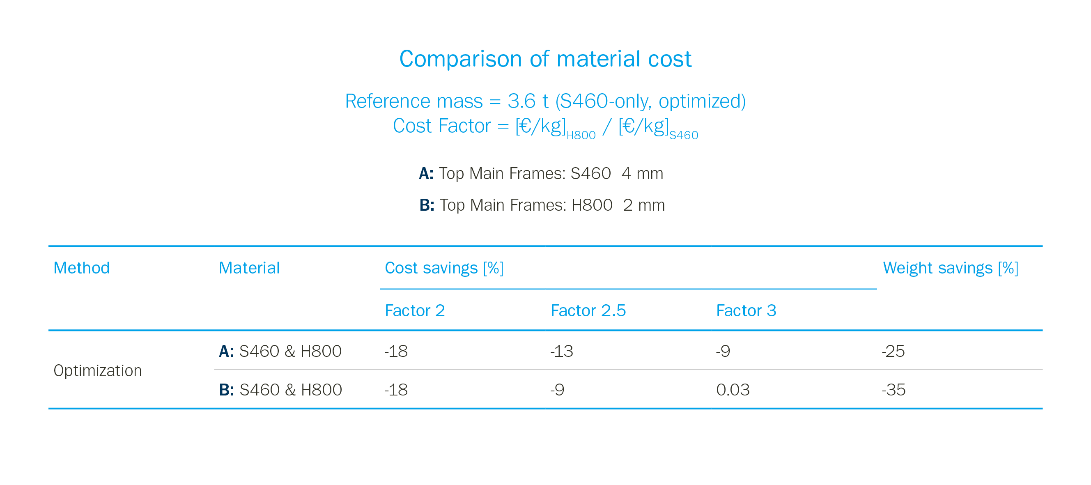

Figure 5 shows the cost impact of changing the frame material. Since relative costs of different steels can vary over time and according to market conditions, three factors were used to scale the cost of Forta H800 relative to S460 – 2, 2.5 and 3 times.

Even with a factor of 3, the weight reduction means that the hybrid structure is comparable in cost to the S460-only structure., while at a factor of 2 the hybrid design represents an 18 % improvement in material costs. In this analysis, only pure material costs were compared and additional aspects such as lightweight design and energy consumption during production were not taken into account.

Looking ahead – next steps

Work is ongoing to further refine the simulation process. There is also scope to investigate more variables, such as materials, cross-sections, wall-thicknesses and junction locations. This would then allow a complete re-design of the bus structure.

The effect of manufacturing techniques is another important factor to be considered in future work. For example, the performance of welded joints under fatigue loading can be improved considerably by refining the joining process and displacing the welded seam away from the most stressed areas. This may even offer the possibility to further reduce the cross-section or wall thickness. It is likely that if the same simulation detailed here was carried out to include refined joining processes, then the difference between the carbon steel and stainless steel structures would be even more significant.

Stainless steel is ready to help the bus and coach industry go lightweight

The bus and coach industry has a reputation for being very traditional in its approach and wary to adopt new materials. However, the transport industry in general is under ever-growing pressure to decarbonize. That is now forcing the pace of change in terms of creating a new generation of vehicles suitable for pure electric or hybrid traction. Energy efficiency will be crucial to their success and that requires the adoption of new lightweight construction methods.

The simulations carried out to date have demonstrated that stainless steel offers significant potential to deliver substantial savings in vehicle weight, with no loss of performance.

The project has also shown that the best use of stainless steel may be as part of a hybrid bus frame structure that offers both weight and cost advantages.