ZF celebrates two million electric motors produced so far

ZF has reached the milestone of two million electric motors produced. “Our production anniversary is backed by long-term entrepreneurial decisions and innovative engineering spirit,” said Stephan von Schuckmann, member of the ZF Board of Management and responsible for Electrified Powertrain Technology. ZF and electric motors: enhancing resources, since 2015 After 2015, when the demand for pure […]

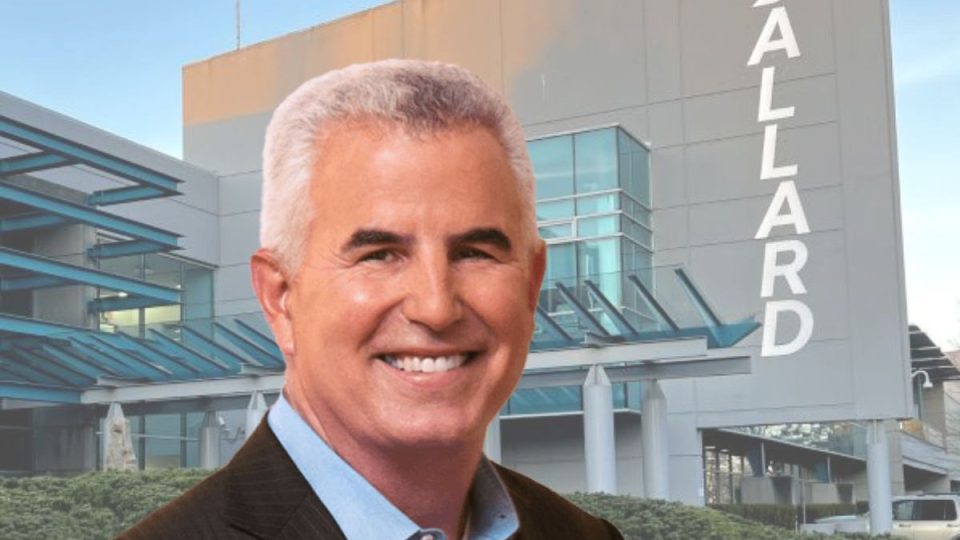

ZF has reached the milestone of two million electric motors produced. “Our production anniversary is backed by long-term entrepreneurial decisions and innovative engineering spirit,” said Stephan von Schuckmann, member of the ZF Board of Management and responsible for Electrified Powertrain Technology.

ZF and electric motors: enhancing resources, since 2015

After 2015, when the demand for pure electric mobility started to become visible, the company placed its focus on a new technology: hairpin winding enables wires to be packed tighter together, which helps increase the power, speeds and torque with the same space. This was necessary because, with purely electric drives, the running speed of the electric motor is no longer coupled with the combustion engine. Hairpin technology can also increase the level of automation in production.

ZF electric motors cover a broad range of applications from mild hybrids and plug-in hybrids to purely electric drive systems for passenger cars and commercial vehicles. The performance range is 50 kW to 550 kW, with torques of 75 Nm to 1,500 Nm.

Production expanded accordingly

In order to keep pace with the global increase in electric vehicle production, ZF has continuously expanded production capacities for electric motors at the lead plant in Schweinfurt, Germany. In addition, the company commissioned major production lines in Pančevo (Serbia) and Shenyang (China) in recent years. Another plant in North America is currently under construction and will go into operation in 2023.

Talking about innovations, in recent years, sophisticated cooling solutions have been introduced in addition to the classic cooling jacket with water flowing through. “Currently we are developing a

solution with oil flowing past – to directly cool the copper wire, which is the main heat source in electric motors”, explained Roland Hintringer, Head of the Electric Motors Product Line.

In view of globally increasing volumes and the high demand for electric powertrain technology, the next production milestone will be reached soon. “Our order books are well filled, the next two million units of electric motors will probably be produced in less than two years,” added Hintringer.