HEIDI project, £12 million to Bramble Energy to develop hydrogen double-decker

Bramble Energy has joined forces with Equipmake, Aeristech and the University of Bath to develop a hydrogen-powered double-decker bus that integrates Bramble’s signature low-cost printed circuit fuel cell (PCBFC) technology.Bramble Energy is the lead partner in the Hydrogen Electric Integrated Drivetrain Initiative (HEIDI), which received a £6.3 million grant from the Advanced Propulsion Centre under […]

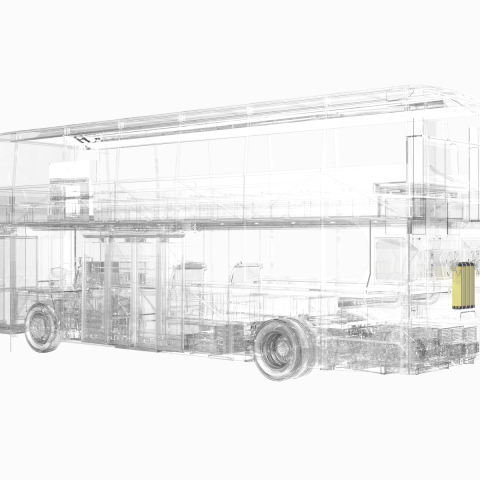

Bramble Energy has joined forces with Equipmake, Aeristech and the University of Bath to develop a hydrogen-powered double-decker bus that integrates Bramble’s signature low-cost printed circuit fuel cell (PCBFC) technology.

Bramble Energy is the lead partner in the Hydrogen Electric Integrated Drivetrain Initiative (HEIDI), which received a £6.3 million grant from the Advanced Propulsion Centre under the Automotive Transformation Fund. The £6.3 million allocated by the government will be matched by industry to the tune of £12.7 million.

Hydrogen buses, the Bramble-Aeristech and Equipmake axis.

The consortium, will develop a hydrogen-powered double-decker bus using unique fuel cell technology from Bramble Energy, a high-efficiency air compressor from Aeristech, and engine power electronics and battery management system from Equipmake. The powertrain will be optimized through vehicle simulations conducted by the University of Bath.

Bramble Energy was selected for this project because of its revolutionary fuel cell design and manufacturing process. Using patent-protected printed circuit board technology, it is able to create custom fuel cell stacks in days, at scale and at low cost. Bramble’s printed circuit board technology eliminates the requirement for a number of complex and expensive components found in a typical electrochemical stack, which not only simplifies the supply chain, but also does not require major retooling for manufacturing.

Fuel cell stacks can be produced in almost any size and arrangement according to the needs of the end customer. The result is an unprecedented economic solution to support and accelerate the decarbonization of public transportation and improve air quality in cities around the world.

Dr Vidal Bharath, CCO at Bramble Energy commented: «Fuel cell technology can deliver a viable net zero solution that lends itself to commercial vehicles where downtime needs to be limited. This consortium of partners means that we will be able to deliver a world-leading hybridized powertrain, utilising our innovative low cost PCBFC™ technology for the bus sector, where there needs to be a viable electrified solution that can deliver on cost and scalability».