What do the colors of hydrogen mean? [The Hydrogen Hub #3]

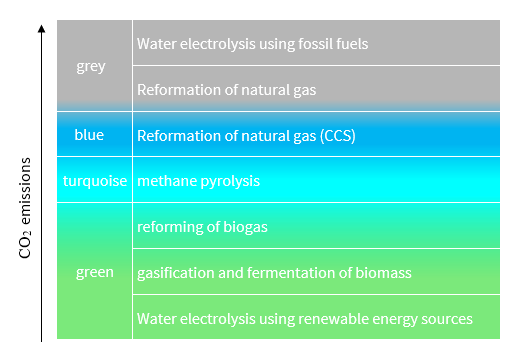

The element hydrogen is naturally colorless, both in gas and liquid phases. However, various designations are currently circulating, such as green, grey, blue and turquoise.

Below, a contribution from EMCEL, a German-based engineering company focusing on hydrogen, fuel cells and e-mobility.

It’s the second of a series of articles on topics around hydrogen economy and applications.

Feedbacks, questions and contributions are welcome (at info@sustainable-bus.com)

The element hydrogen is naturally colorless, both in gas and liquid phases. However, various designations are currently circulating, such as green, grey, blue and turquoise. These labels refer to the production of hydrogen and the associated direct and indirect CO2 emissions. Here you find explanation about the different colors of hydrogen and their specific advantages and disadvantages.

Green hydrogen

Green hydrogen is produced exclusively from renewable energy sources. For this purpose, the process of water electrolysis is primarily used, in which water is split into its components hydrogen and oxygen using electricity. Other ways to produce green hydrogen are through gasification and fermentation of biomass and reformation of biogas. All these processes are CO2-neutral, which is why the hydrogen produced can be declared as green hydrogen.

Advantage: CO2-neutral generation

Disadvantage: Production is comparatively cost-intensive today

Grey hydrogen

Grey hydrogen is characterized by the fact that it is produced using fossil fuels. The currently most common process is steam reforming, in which natural gas is converted into hydrogen and CO2 under the influence of steam and heat. Electrolysis using the current electricity mix may also be considered grey due to still high CO2 emissions affecting energy sector.

Advantage: Cheap large-scale production

Disadvantage: CO2 emissions, further dependence on fossil fuels

Blue hydrogen

The production of blue hydrogen is equivalent to the production of grey hydrogen in relation to the use of primary energy. The difference in the colors is that the CO2 released is stored underground using CCS (carbon capture storage) technology or processed in industry. As a result, the hydrogen can be considered CO2-neutral in the carbon footprint.

Advantage: Relatively cheap and CO2-neutral in terms of overall balance.

Disadvantage: CO2 storage is limited, long-term effect is controversial

Turquoise hydrogen

Turquoise hydrogen is produced by methane pyrolysis, in which methane is broken down into solid carbon and hydrogen in a thermochemical process. As long as the heat supply for the high-temperature reactor is provided from renewable energy sources, it is a CO2-neutral process in terms of overall balance.

Advantage: Solid carbon can be reused in industry

Disadvantage: Carbon safeguarding is challenging, still in pilot phase

By-product hydrogen

In the chemical industry, large quantities of hydrogen are produced during chlor-alkali electrolysis, in addition to the target products chlorine and caustic soda. By-product hydrogen is officially not assigned to any color yet.

Advantage: Hydrogen is produced as a by-product

Disadvantage: Chlor-alkali electrolysis is energy-intensive, the hydrogen is only available regionally

Conclusion

In the introductory and transitional phase, various existing hydrogen potentials can be used to move closer to the goal of a national hydrogen infrastructure. However, attention should be paid to ensuring that the generation processes used releases as little additional CO2 as possible and that long-term dependencies are avoided. In the long term, hydrogen must become 100% green – in line with the advancing expansion of renewable generation capacities.