The Battery Cycle: shedding light on batteries through a series of knowledge articles [2025 RELEASE]

Four years ago, with insights from Claudius Jehle, CEO of volytica diagnostics GmbH, we launched “The Battery Cycle” series of articles, aiming to shedding light on the complexities of Li-Ion batteries.The series provided a huge amount of valuable insights for anyone involved in electric mobility.Now, four years later, we return to those same topics—still thanks […]

Four years ago, with insights from Claudius Jehle, CEO of volytica diagnostics GmbH, we launched “The Battery Cycle” series of articles, aiming to shedding light on the complexities of Li-Ion batteries.

The series provided a huge amount of valuable insights for anyone involved in electric mobility.

Now, four years later, we return to those same topics—still thanks to the collaboration with Claudius Jehle—enriched by real-world data and lessons learned.

We welcome your questions, feedback and contributions at info@sustainable-bus.com.

The battery is the last relevant remaining wearing part of an electric vehicle – and by far the most expensive. Apart from tyres and wipers, there’s no oil change, no complex exhaust system and even braking is largely done by the engine itself, sparing the mechanical brakes.

Together with modest electricity prices, battery-electric transport should thus in principle be a care-free, straightforward and especially economical alternative to our well-known ICE vehicles.

However, in practice there are several challenges, sometimes bad media coverage and especially a huge information asymmetry around this complex component onto which we put so much focus and hope.

Reason enough to take a closer look and debunk some myths of this delicate blackbox.

Battery analytics in 2025 – more relevant than ever

In less than four years, the European e-bus market has experienced significant growth. Currently, battery-electric buses account for 46% of new city bus registrations in the EU. In countries such as Norway, Slovenia, Denmark, and the Netherlands, the share of zero-emission buses has reached 100%.

With dozens of manufacturers (OEMs), both legacy and evolving battery chemistries like lithium iron phosphate (LFP) and nickel cobalt aluminum oxide (NCA), and growing regulatory pressure, the battery has transitioned from a mysterious component to a mission-critical one. Although it remains the most expensive and sensitive component of the vehicle, the battery now plays a strategic role in safety, lifetime planning, and residual value.

In this updated series, we revisit key battery topics and shed light on what has changed — and what still needs to change — as e-bus fleets mature.

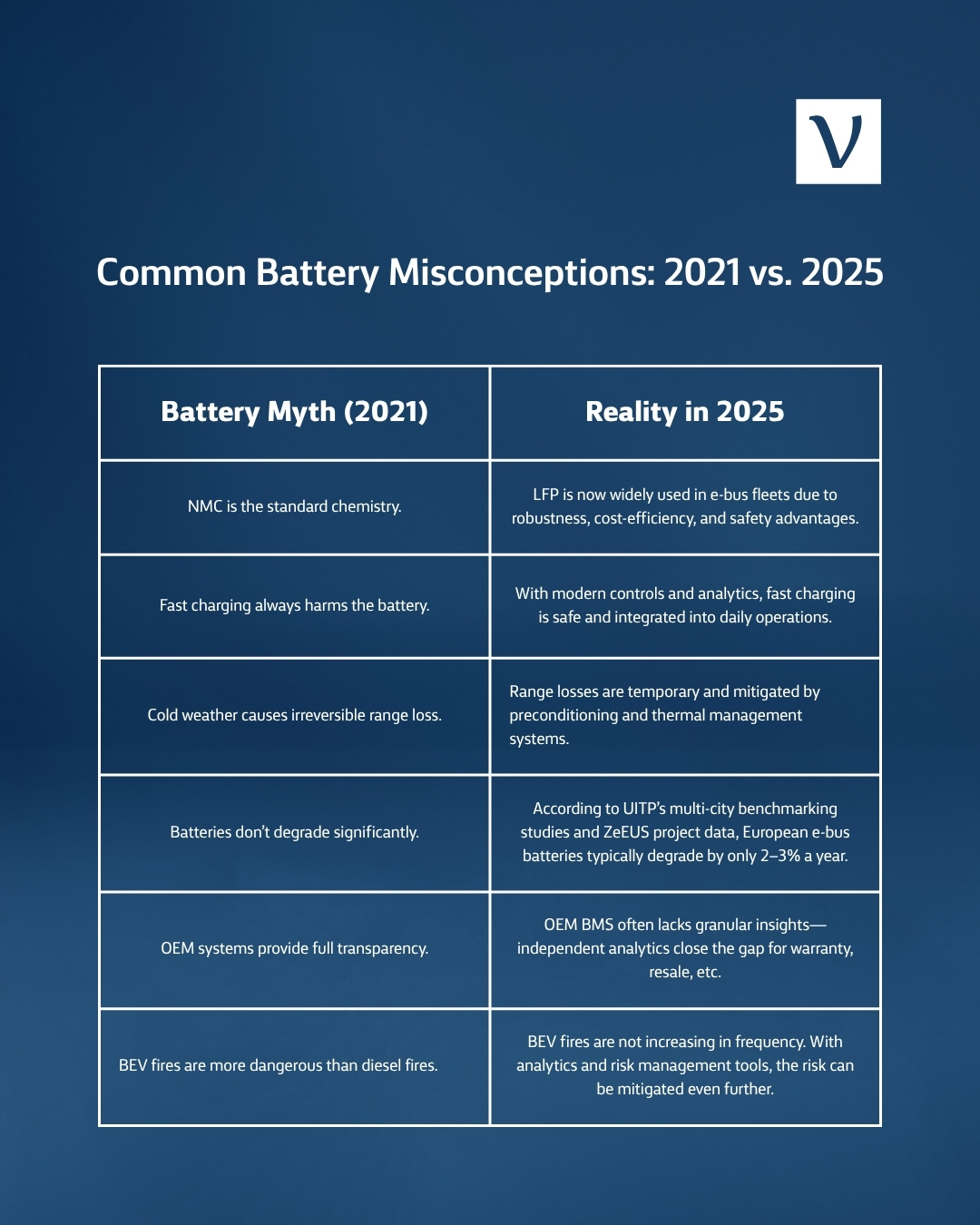

Common misconceptions (2021 vs. 2025)

In our original 2021 article, we aimed to demystify the battery – highlighting myths and misunderstandings. Here’s how these myths hold up in 2025:

Looking ahead in the series

In the coming months, we’ll dive deeper into topics including battery chemistries, SoC accuracy, degradation, balancing, second-life value and more—always with hands-on operator value in mind.

Hands-on Tip #1

Start building your “battery passport” today – even before it’s mandatory. Assign unique IDs, collect key metrics like SoH, charging behavior and temperature profiles, and document anomalies.

Include these requirements in your tenders: it supports resale value, warranty negotiations, and future compliance.

Unsure which KPIs matter most? Contact volytica to define them for your use case.