PEI Mobility, the importance of dynamic simulation in development of high-tech products

The dynamic simulation in vehicle design is an important virtual analysis and testing tool that has been supporting physical tests made in automotive industry for a long time now. In particular, the sector of urban bus design is a theme of great interest for research in the automotive world, both in terms of performing features […]

The dynamic simulation in vehicle design is an important virtual analysis and testing tool that has been supporting physical tests made in automotive industry for a long time now. In particular, the sector of urban bus design is a theme of great interest for research in the automotive world, both in terms of performing features and considering safety and comfortable mobility for passengers.

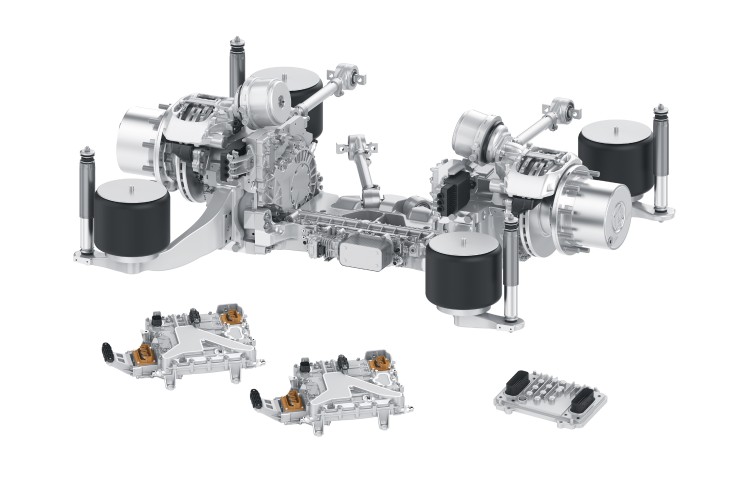

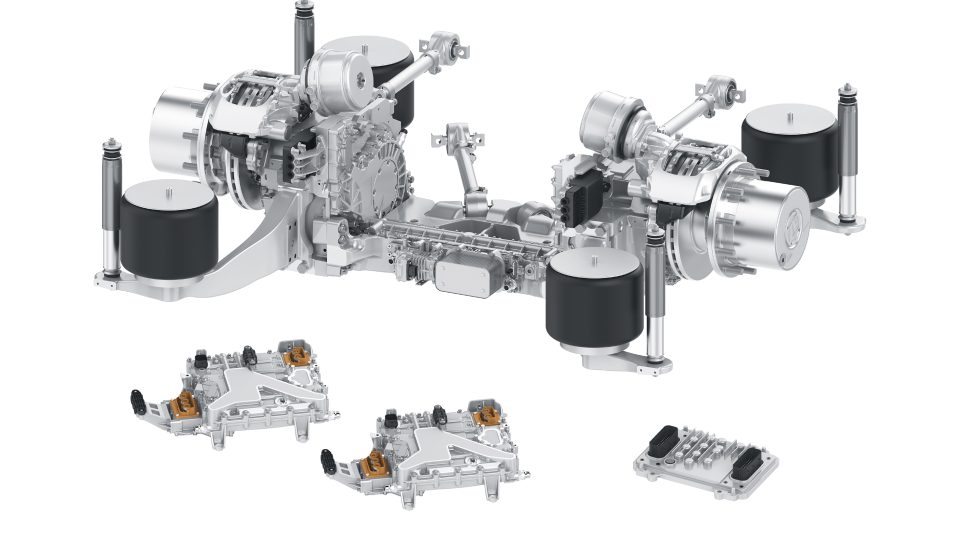

In this specific context, the R&D department of PEI Mobility, the renewed BU of PEI Srl specialised in supplying bellows, articulations and gangway systems, has been working since long ago with special state-of-the-art multi-body softwares, to create solutions being the primary aim to optimise road transport. Through these cutting-edge technologies and thanks to an experienced and qualified team of engineers, PEI Mobility anticipates the market needs by developing high-tech products in terms of performance and safety.

PEI Mobility’s test area

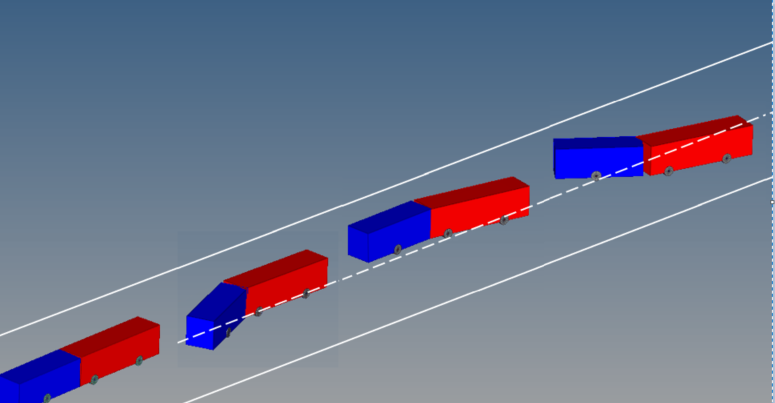

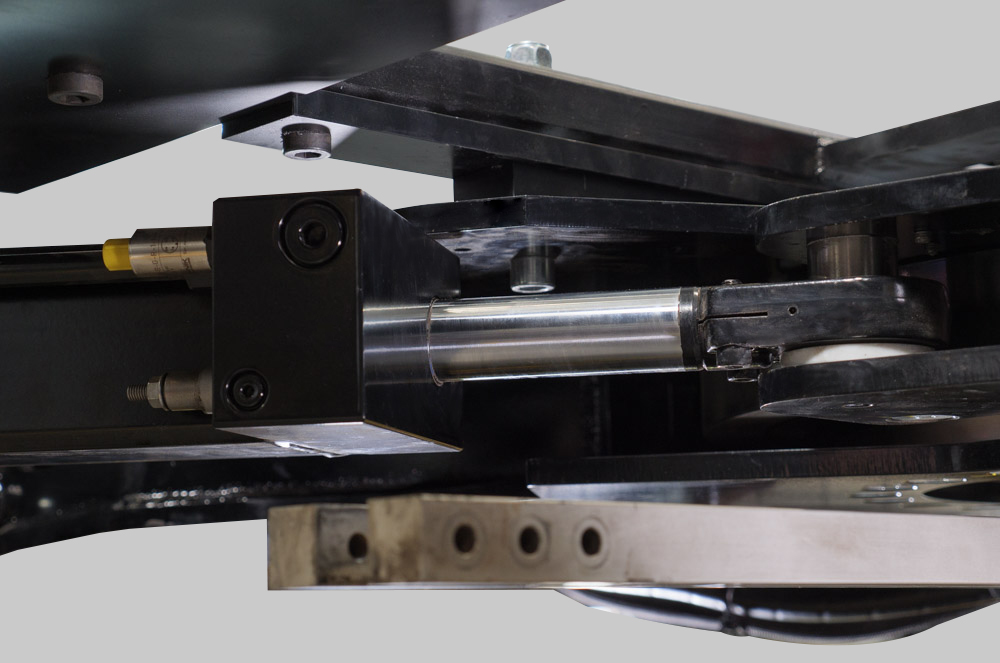

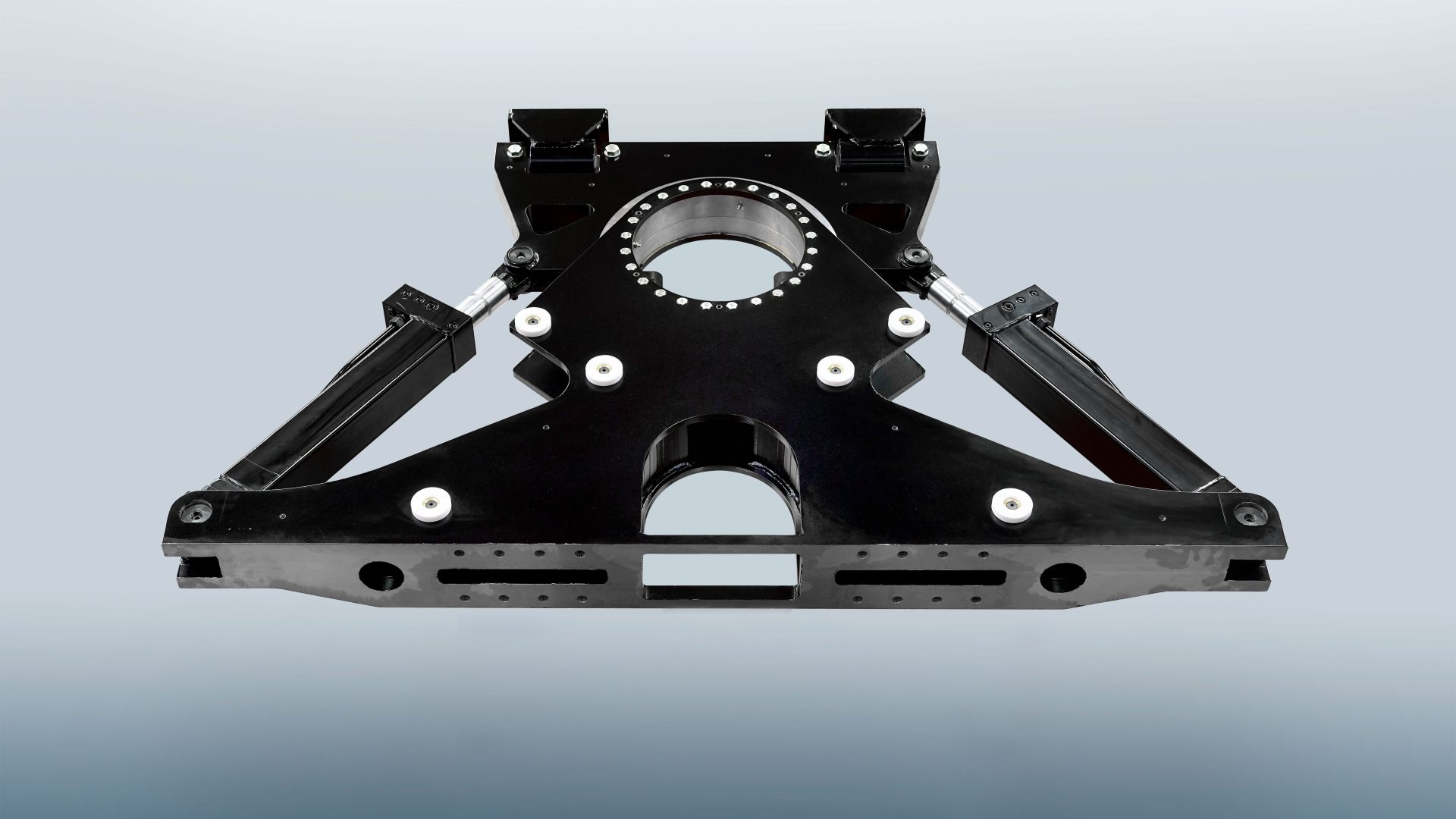

A clear-cut example is given by the new articulated bus joints recently presented by company with headquarter in Bologna, whose hydraulic damping system was designed and tested using simulations originated from the construction of numerical models, based on the equation of motion of real buses. The software performing these simulations in fact reproduces every part of the bus chassis to be tested: from the axle, to the carriages up to even the passengers themselves. It provides the required dynamics and responses about vehicle instability in case of specific dangerous situations. This involves a real test area set up by technicians and engineers at the plant located in Zola Predosa (Bologna, Italy).

Therefore, the dynamic simulation allows PEI Mobility to examine the performance of the hydraulic damping system by actually predictive testing each bus on which it will be installed, with the imperative to meet the safety parameters established by the most authoritative safety certification bodies.

PEI Mobility’s bus design

PEI Mobility thus commits to solve one of the main issues related to the design of buses, the event known as “Jackknife”, typical of the articulated vehicles. In this field, this term represents a dangerous operation condition that leads to loss of trailer control and compromises maintaining of the vehicle trajectory.

To prevent the above one and other possible critical problems, PEI Mobility adjust each damping device according to the structure of the vehicle it will serve, in a more effective way than the traditional standards. This is a real extra edge of the company, which offers a unique level of customisation, designing tailor-made systems and settings for each type of vehicle based on the numerical simulation models as said above. The high reliable technical and design expertise that distinguishes PEI Mobility is the result of a management inspired by the continuous search for solutions for matching advanced safety standards needs in urban mobility, supported by constant and significant investments.