Teamtechnik to provide production line for Impact’s gigafactory in Poland

Teamtechnik Production Technology will provide production line for Impact gigafactory. Impact Clean Power Technology (Impact), is to set up a factory for battery systems for electric vehicles, with a target production of 4GWh per year. The project for establishing GigafactoryX in Poland by Impact was announced in July 2022. Battery cells provider? InoBat. Among electric […]

Teamtechnik Production Technology will provide production line for Impact gigafactory. Impact Clean Power Technology (Impact), is to set up a factory for battery systems for electric vehicles, with a target production of 4GWh per year.

The project for establishing GigafactoryX in Poland by Impact was announced in July 2022. Battery cells provider? InoBat. Among electric bus manufacturer turning to Impact battery technology we find Alexander Dennis.

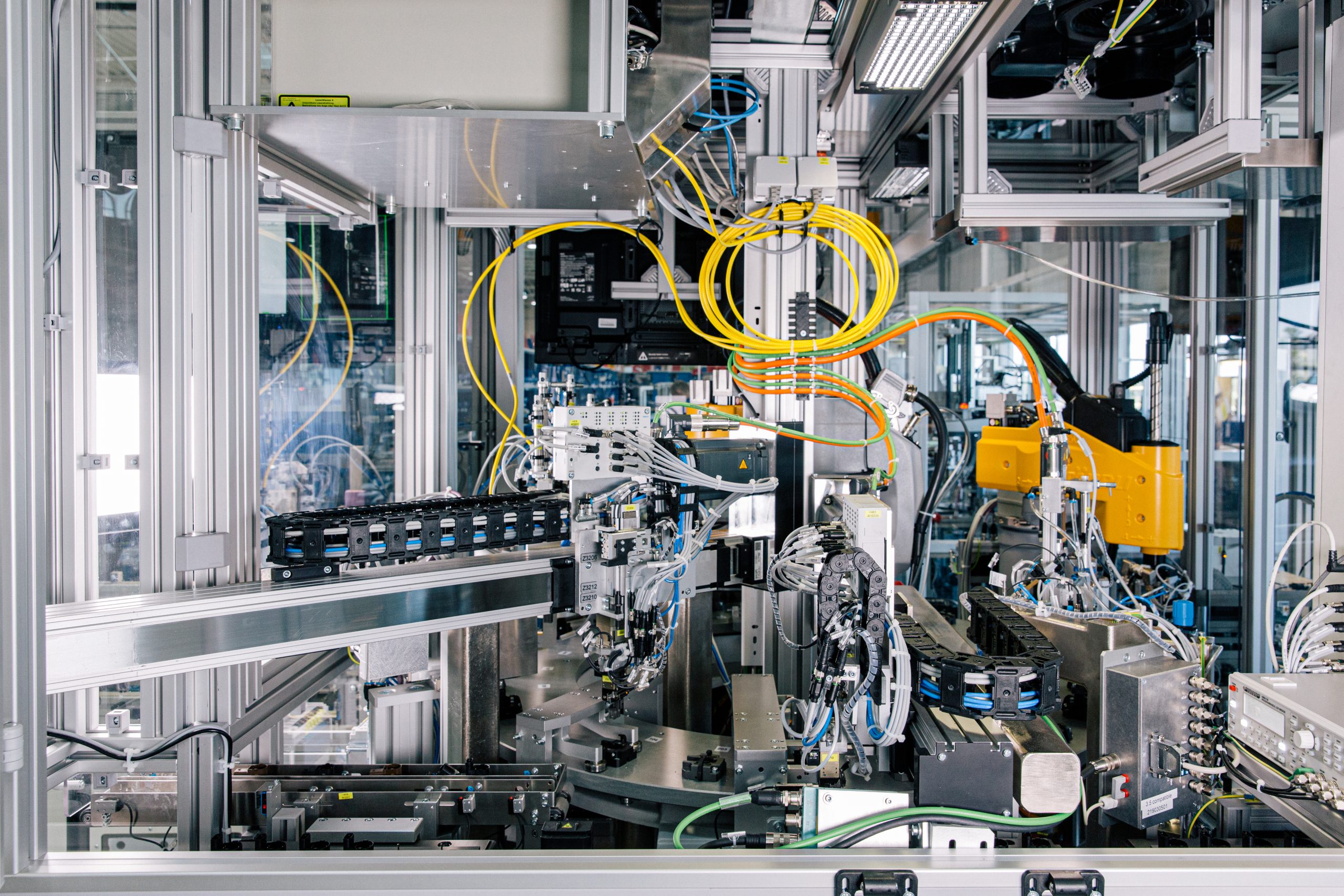

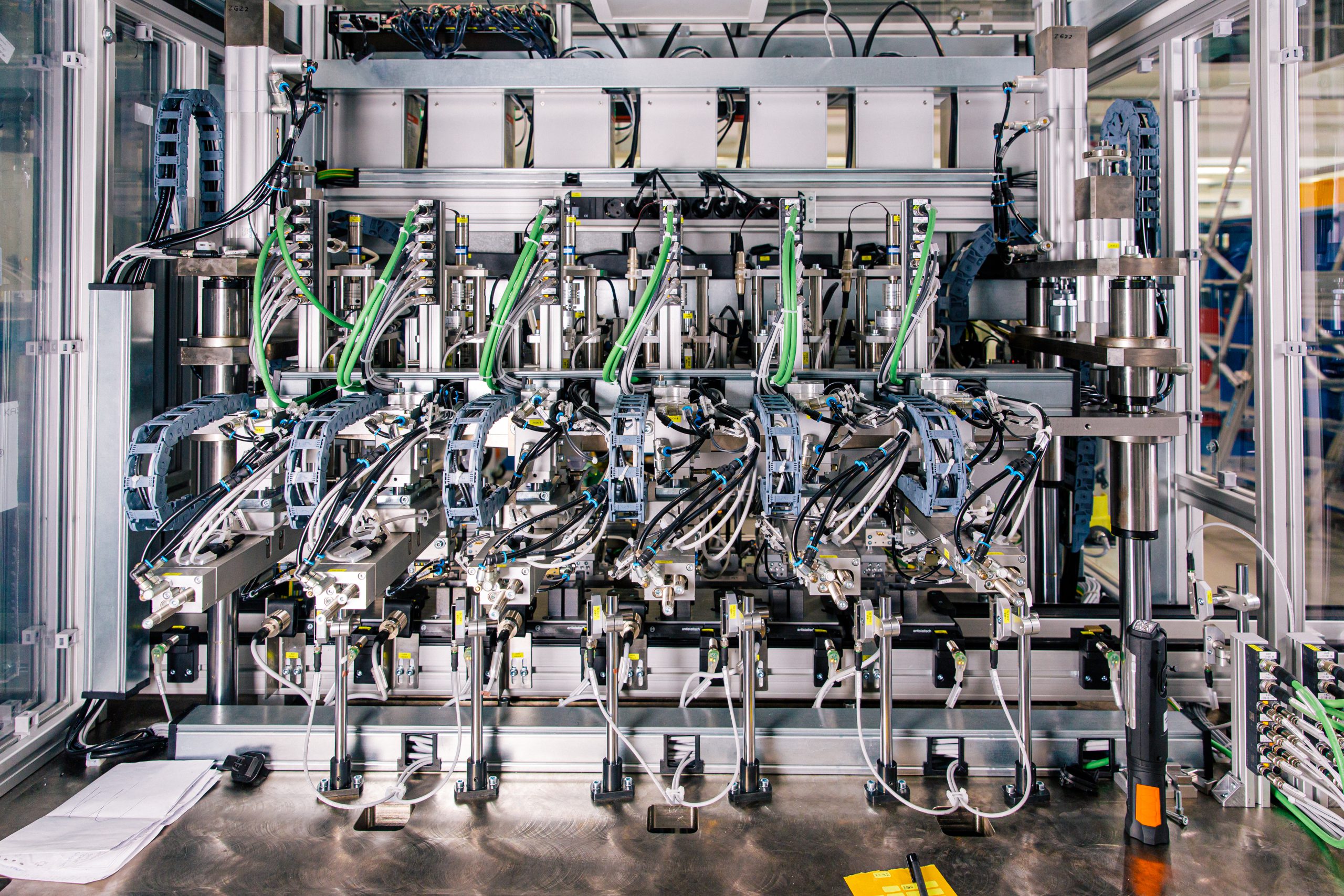

Teamtechnik Production Technology (teamtechnik PT) specialises in building customised automated assembly lines for the mobility, industrial goods and life science industries. It’ll implement a state-of-the-art line at GigafactoryX to produce batteries for buses, trolleybuses, trams and trains, among others.

The design phase is expected to continue until the end of April this year, with assembly work slated to begin in July 2023.

Teamtechnik for GigafactoryX by Impact Clean Power Technology

The contract for the delivery of the production line to GigafactoryX was concluded at the end of 2022. The design phase is currently underway. As part of the project, teamtechnik will build a production line for battery systems for, among other things, electric buses in three variants. The line will be suitable for further expansion, it is underlined.

“An example of the dimensions of a battery produced for one key customer is 1400 mm x 1000 mm x 400 mm. The dimensions of the individual batteries vary not only in size but also in weight, which can reach up to 500 kg. Already in 2024, the line will allow 16,000 battery systems for e-transport to be produced. The line will feature a high standard of process automation including robotic assembly of individual components, dispensing processes, screwing, vision inspection and a range of tests”, Impact says.

The GigafactoryX project will involve the construction of a large-scale battery factory for electric vehicles and stationary energy storage, utilizing lithium-ion cells in LTO, LFP, and NMC technologies. Once completed, this will enable the production of power systems in Poland, with a planned capacity of 16,000 units in 2024 and 17,000 units from 2025.

The use of these technologies will also allow for a assembly cycle of 11 minutes per battery.

Teamtechnik production line Impact Gigafactory

“Thanks to the investment, Impact’s production capacity will be significantly increased. The first phase of the investment will increase them to 1.2GWh per year, which will guarantee the security of supply of battery systems for the world’s biggest brands. Ultimately, production will reach 4GWh per year. Its current level is 0.6GWh per year,” comments Ireneusz Kazimierski, Impact’s vice-president for operations.

“The construction of the production line is a key step towards the further development of the GigafactoryX project. With highly automated processes, we are not only increasing production efficiency, but also the reproducible quality of the batteries produced. Therefore, production will be carried out with full product traceability, a product management policy in case of non-conformity and its correction or repair,” says Bartek Kras, CEO and co-founder of Impact.

“From a teamtechnik PT point of view, this is the largest battery line project in the company’s history in Poland. In it, we rely on proven solutions backed by our extensive experience in designing and building lines with different levels of automation, which we have been successfully implementing for over 16 years. At the same time, we are not afraid to use state-of-the-art technologies. All of this is aimed at delivering the highest quality of the end product, which is the battery” says Wojciech Derda, president of teamtechnik Polska.