Lithium-ion battery technology in e-buses, according to BMZ Poland

Lithium-ion batteries have entered every segment of our lives. From mobile phones and power tools to e-bikes and cars. The race for more energy and more power is on. The main driver behind that race is the progress of technology used in li-ion cells and batteries. The key parameter for any electric vehicle is energy […]

Lithium-ion batteries have entered every segment of our lives. From mobile phones and power tools to e-bikes and cars. The race for more energy and more power is on. The main driver behind that race is the progress of technology used in li-ion cells and batteries.

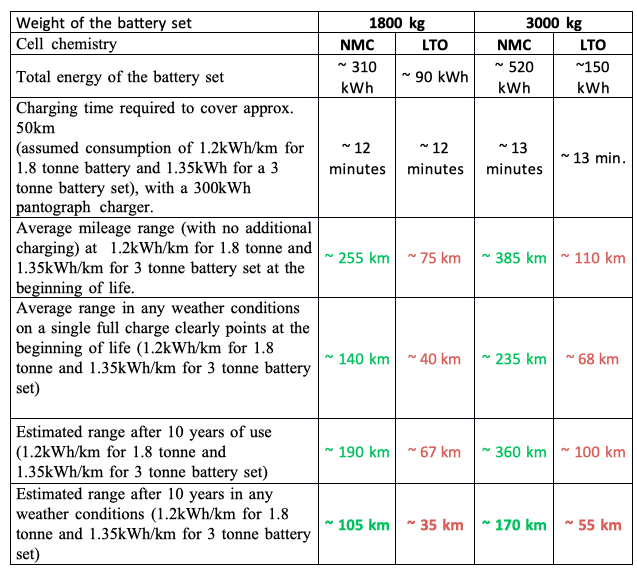

The key parameter for any electric vehicle is energy consumption measured in kWh/km. It’s predominantly connected to the vehicle’s weight. So in the e-bus segment the race to reduce the total weight of the batteries to gain the highest energy density is really fierce.

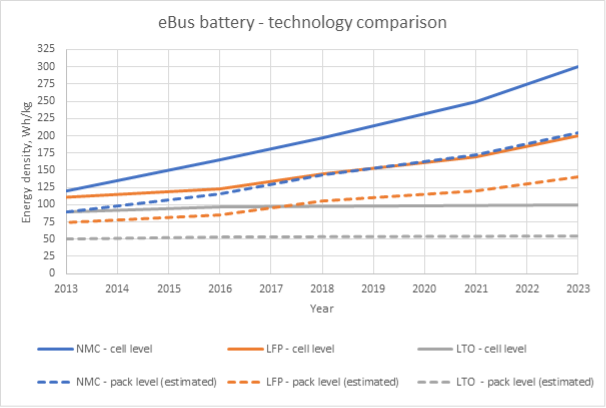

The three most popular types of lithium-ion technologies are LTO, LFP and NMC (the acronyms derive from the type of minerals used in the cell chemistry: we have explained them deeply here). Each of them have some unique characteristics but, according to BMZ Poland, «it is NMC that has been winning the race thanks to its universality in both car and commercial vehicle applications. Not only does it win the energy density contest, but it is also the leader when it comes to unit weight and volume».

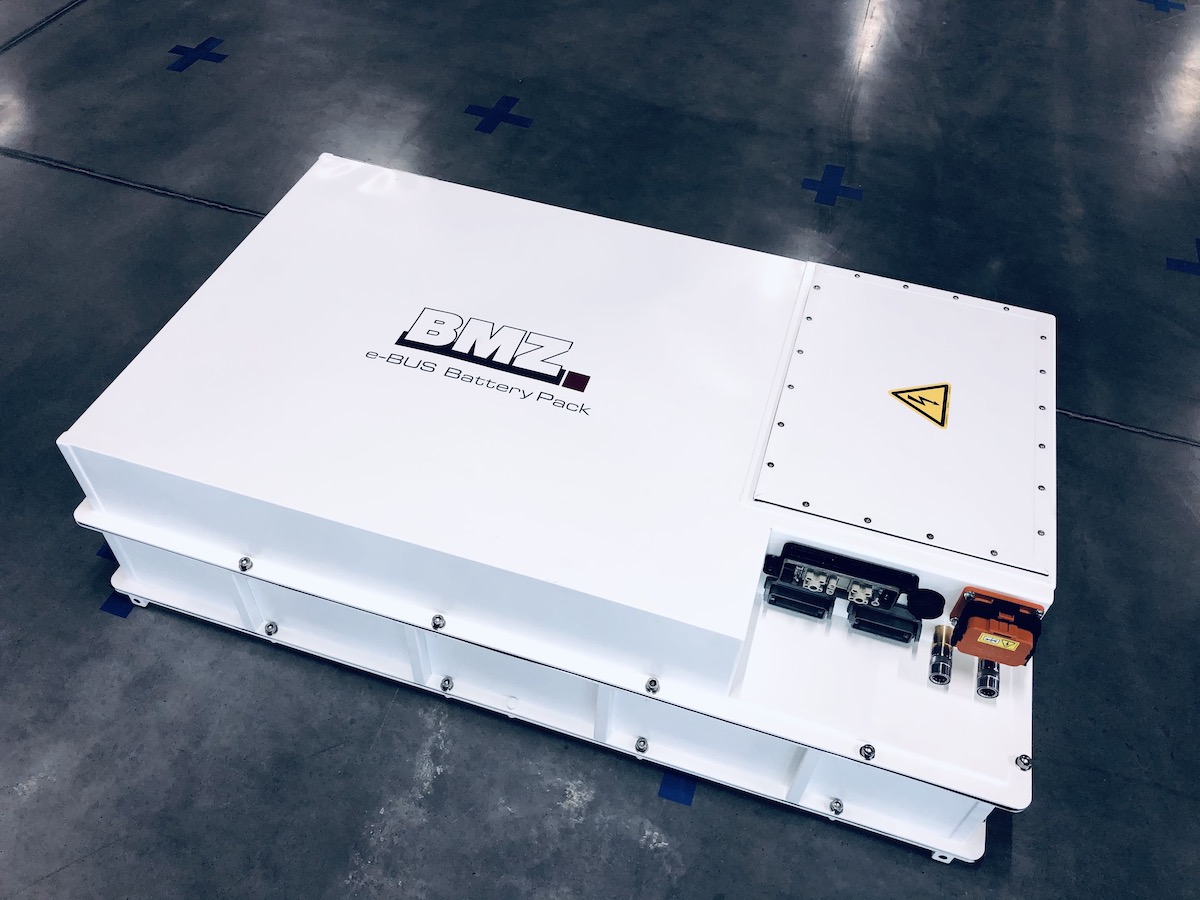

The BMZ Group has manufacturing facilities in China, Poland, and the US, as well as offices in Japan, UK and France with 3,000 employees on more than 200,000 square meters of production space. A 150-people development team works on the lithium-ion battery technology from prototype construction to the planning and implementation of efficient series production. The group realizes more than 250 projects every year, from the idea to the product, including intelligent charging technology and a communication interface.

BMZ and the challenge between NMC and LTO batteries

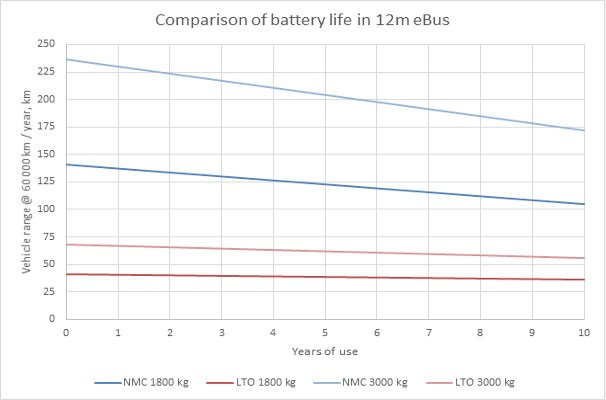

The graph begs the question whether the reason for the stagnation in the LTO development is the significantly improved performance of the recent NMC technology? The gap in the pantograph charging options reserved for LTO only a couple of years ago has been bridged by the latest developments in the NMC chemistry/segment. BMZ Poland adds: «The increasing versatility and performance of NMC captured a major proportion of the EV market and drove enormous investment in new developments across the world. LTO is pursued by only a handful of seasoned manufacturers. Subsequently, the lifetime of the vehicles powered by the new NMC technology go often head-to-head with the ones using LTO. There’s also a little bonus going with it: substantially greater distance that e.g. an e-bus may cover until the end of its “lifetime”».

The figures shows that comparative analysis for a 10-year battery use between LTO and NMC shifts the scales towards the latter: «When LFP chemistry is thrown into the equation, its performance is comparable to what NMC offered 5 years ago. Today’s NMC delivers even 40% more energy density over LFP when contemporary technologies of both chemistries are compared».

BMZ new MAGNUS+ battery, up to 700 kWh

Consequently, it’s not surprising why NMC is gaining ground as cell and battery manufacturers continue to invest heavily in further developments. BMZ Poland’s latest premiere of MAGNUS+ is part of this trend. This new generation of the Rechargeable Energy Storage System (RESS) scalable to 700kWh has in the versatility its distinguishing feature. It is also worth noting that the producer declares the ability to cover ever up to one million kilometers throughout the lifetime of the system.

Moreover, the technology offered in MAGNUS+ has the goal of eliminating the compromise where customers had to choose between High Power or High Energy characteristics of the battery system, as it has been developed in order to satisfy both of those performance requirements. The product is then suitable for a vast variety of vehicles: from electric or hybrid buses, to trolley buses or trams. It will also serve such distant types of applications like last-mile-delivery vans or… trains. Suffice to say that any other traction type of application will work with MAGNUS+ just fine, e.g. diggers, dumpster truck, lorries, autonomous vehicles or road-sweepers. Surely this is not their final word and the market will watch this race with utmost attention.