New generation blade battery by BYD close to launch (with 190 Wh/kg energy density expected)

BYD’s blade battery is close to be launched in a new version, “possibly in August“, CarNewsChina writes. The current generation of the battery is set to be used on the new 12-metre BYD eBus platform B2, integrated to the chassis (showed at Busworld 2023 in Brussels). In early 2024 BorgWarner announced a strategic relationship agreement with […]

BYD’s blade battery is close to be launched in a new version, “possibly in August“, CarNewsChina writes. The current generation of the battery is set to be used on the new 12-metre BYD eBus platform B2, integrated to the chassis (showed at Busworld 2023 in Brussels).

In early 2024 BorgWarner announced a strategic relationship agreement with BYD battery division FinDreams so that the group will be in charge of manufacturing LFP battery packs for commercial vehicles utilizing FinDreams Battery blade cells in Europe, the Americas, and select regions of Asia Pacific. The duration of the agreement is 8 years.

BYD: new generation blade battery coming

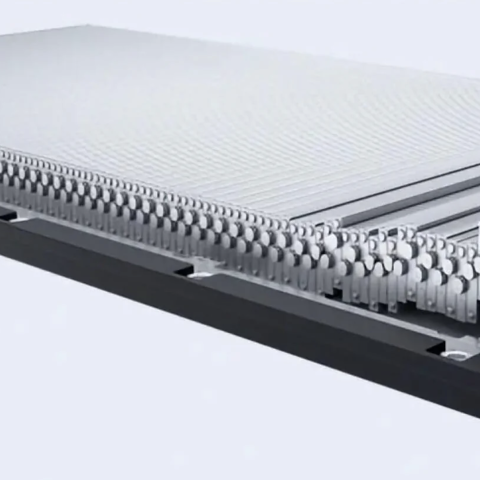

Dr. Martin Busche, Director Global R&D at BorgWarner Battery Systems told Sustainable Bus in an interview held in March 2024 that “FinDreams will supply BorgWarner with their LFP blade battery cells and production equipment. The design of the LFP battery packs is fully done by BorgWarner, but with using some intellectual property of FinDreams Battery to be able to design the packs to be manufactured on production equipment that is evolved out of existing production lines already in production at FinDreams Battery. The term blade battery refers to its structural design with a long metal can and side terminals as a major differentiator to commonly used top terminal prismatic cells. Moving the terminals to the shortest side of the cell brings benefits in volume occupancy and cooling performance”.

Back to the new generation blade battery by BYD to reports from Chinese media covered by trade agency electrive, citing BYD CEO Wang Chuanfu, the energy density of the next iteration of LFP batteries is slated to reach 190 Wh/kg, a significant improvement from the 140 Wh/kg achieved when the first generation was introduced in 2020. Furthermore, with recent enhancements, the current energy density of the blade battery stands at 150 Wh/kg. Additionally, the upcoming second generation is expected to be more compact and facilitate reduced power consumption per 100 kilometers traveled.

According to statements dating back to the battery model launch in 2020, the singular cells are arranged together in an array and then inserted into a battery pack. Due to its optimized battery pack structure, the space utilization of the battery pack is increased by over 50% compared to conventional lithium iron phosphate block batteries, BYD points out.

While undergoing nail penetration tests, the Blade Battery emitted neither smoke nor fire after being penetrated, and its surface temperature only reached 30 to 60°C, reports the manufacturer. Under the same conditions, a ternary lithium battery exceeded 500°C and violently burned, and while a conventional lithium iron phosphate block battery did not openly emit flames or smoke, its surface temperature reached dangerous temperatures of 200 to 400°C. This implies that EVs equipped with the Blade Battery would be far less susceptible to catching fire, even when they are severely damaged.

“It’s believed that the second-generation blade battery will not only improve the energy density, but also optimize the size, weight and power consumption of the battery pack, further improving the range and performance of electric vehicles”, CarNewsChina adds.